What is High Strain Rate Nanoindentation?

High strain rate nanoindentation is a sophisticated materials testing technique. It has emerged as a crucial tool for the mechanical characterization of materials at the nanoscale, particularly in understanding their mechanical properties under rapid deformation.

The methodology behind this technique extends the conventional nanoindentation process, which involves pressing a hard tip into a material to measure its mechanical properties. By incorporating high strain rates, this allows researchers and engineers to simulate and analyze conditions that materials might experience in high-speed impacts, explosions, or other dynamic events.

Below you will learn more about high strain rate nanoindentation. As well as this, you will find out about its advantages and how it is applied in different areas.

An Introduction to Nanoindentation

Nanoindentation, at its core, is a technique used to provide the mechanical properties of materials at the nanometer scale.

The tip of an indenter is small, sometimes as little as 10 nm, and sharp. When learning about the tip of the identors’ area function, fused silica can be used with it as a reference before an experiment is undertaken.

Applying nanoindentation involves using a controlled force on the surface of a material. Mechanical property measurements are then taken of the indenter’s penetration depth into the contact area. Sometimes flat punches are used as indenters to make the results of the process more visible.

This method provides precise measurements of hardness, elastic modulus, and other material properties at micro to nano scales. Traditional nanoindentation tests are typically conducted at relatively low strain rates, focusing on the quasi-static behavior of materials.

The Need for High Strain Rate Testing

The advent of high strain rate nanoindentation arose from the need to understand material behavior under rapid loading conditions. These conditions are relevant to numerous applications in the aerospace, automotive, defense, and electronics industries.

Materials subjected to high-speed impacts or rapid stress changes exhibit different properties than those measured under static conditions. High strain rate nanoindentation allows for the exploration of these dynamic responses. It offers insights into deformation mechanisms, fracture toughness, strain rate sensitivity, and phase transformations of materials under extreme conditions.

Methodology and Advancements

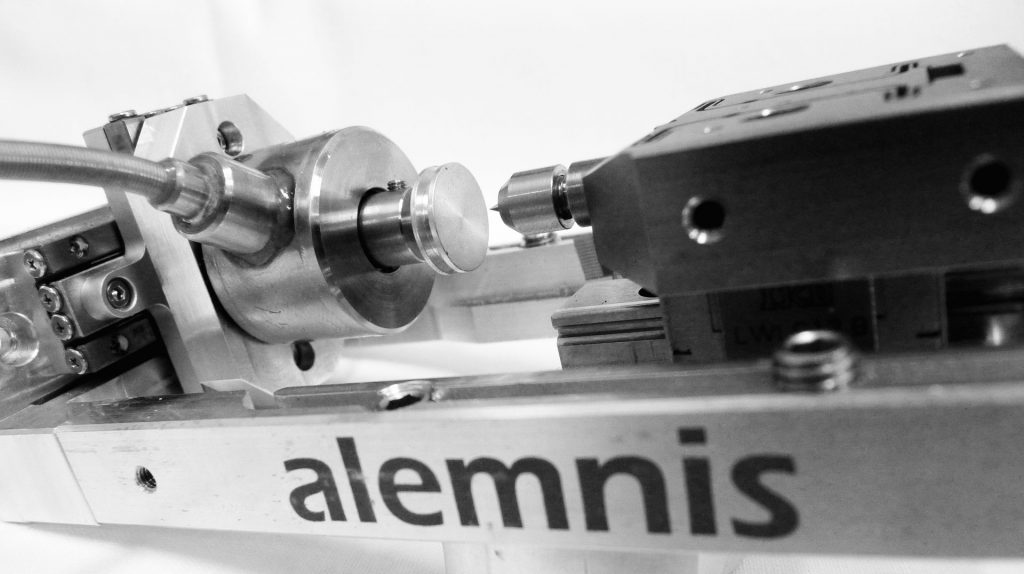

High strain rate nanoindentation is performed using specialized equipment capable of applying extremely rapid displacement of the indenter tip.

Recent advancements have introduced additional techniques:

- Piezoelectric actuators that can achieve high displacement rates

- High-speed data acquisition systems, which capture the transient responses of materials during indentation.

The indenter’s shape is chosen based on a specific material or the desired information. Usually it is a Berkovich indentation tip, a spherical tip, or a custom geometry,

One of the significant challenges in high strain rate nanoindentation is accurately measuring the mechanical response of materials. Namely, this is because of the short time scales involved. Advanced methodologies now include ultra-fast displacement and force sensing technologies, coupled with sophisticated data analysis algorithms, to accurately capture the material’s response.

Recent Advances in High Strain Rate Nanoindentation

High strain rate nanoindentation has witnessed significant advancements. Recent studies explore various materials, from microcrystalline cellulose to high-entropy alloys and structural steel, under extreme conditions.

These studies have employed innovative nanoindentation techniques to unravel the complex interplay between material properties, strain rate sensitivity, and deformation mechanisms.

Implications and Applications of High Strain Rate Nanoindentation

The insights gained from high strain rate nanoindentation are used across various fields, including in the examination of thin films.

For materials science, it aids in the development of materials with tailored properties for specific high-speed applications. Examples of this are protective gear, automotive components, and aerospace structures. Furthermore, understanding the dynamic behavior of materials at the nanoscale is critical for advancing nanotechnology applications, including nanoelectronics and nanocomposites.

High strain rate nanoindentation represents a critical advancement in the field of materials science. It offers a window into the dynamic behavior of materials under conditions that mimic real-world applications. Tensile tests are still useful for determining the yield properties of materials. However nanoindentation is much easier to use for sample creation.

As technology advances, the methodology continues to evolve, providing more detailed and accurate insights into material properties at the nanoscale. This technique not only enhances our understanding of material science but also drives innovation in designing materials and devices for future applications.

Are You Ready to Utilize High Strain Rate Nanoindentation?

As we navigate the intricate landscape of materials science, the significance of understanding and characterizing materials at the nanoscale cannot be overstated. High strain rate nanoindentation offers a window into the mechanical behaviors of materials under dynamic conditions. This is a crucial aspect for advancing technology and engineering materials for tomorrow’s needs.

For those poised to take their indentation testing methods and nanoindentation experiments to the next level, Alemnis provides state-of-the-art nanoindentation solutions. These are tailored for the precise determination of elastic modulus. They can also provide information about critical mechanical properties in a wide range of materials. We encourage you to explore the potential that Alemnis nanoindenters offer in pushing the frontiers of materials characterization. Learn more about how our nanoindentation technology can transform your research and contribute to groundbreaking discoveries by reading our detailed guide on determining elastic modulus with nanoindenters. Embrace the future of materials science with Alemnis at your side.