TOMOGRAPHY

Several challenges exist when designing an in-situ mechanical testing assembly compatible with X-ray beamlines for computed tomography. The assembly must be light weight as it must often be mounted on top of several motion stages. Also, the weight of the load frame must be distributed as symmetrically as possible about the rotational axis. In addition, the assembly must be sufficiently open to allow unrestricted passage of the X-ray beam.

The Alemnis Standard Assembly (ASA) fulfills all the aforementioned requirements for compatibility: it is lightweight yet rigid, axisymmetric about the rotational axis and has a very open architecture which is more than enough for most experiments. In addition, the compact nature of the ASA means that the sample can be brought closer to the X-ray source, which improves image resolution. For specific angles, or for full rotational tomography, the side-frame elements can be replaced with an X-ray transparent material.

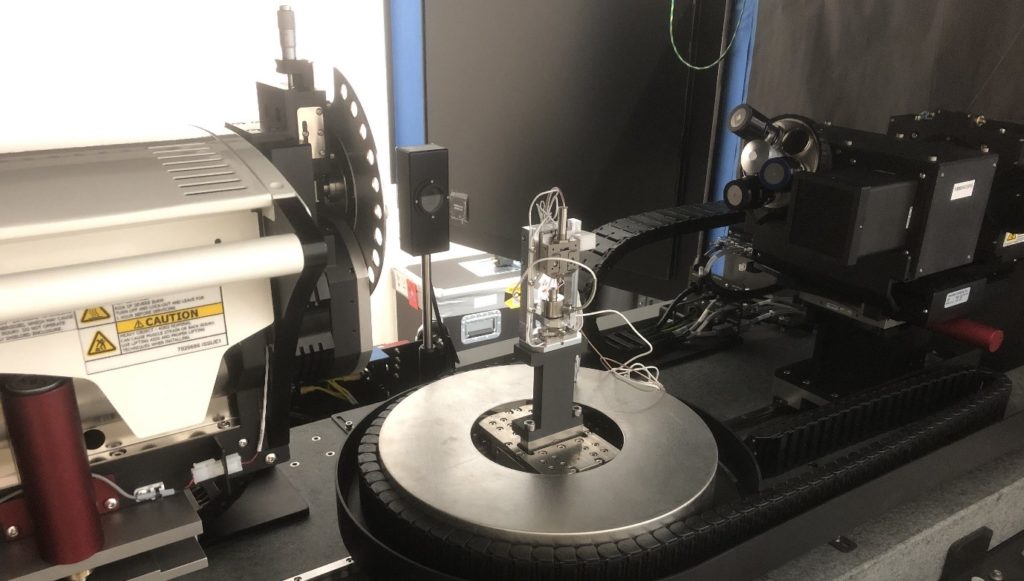

Alemnis Standard Assembly (ASA) mounted vertically in a commercial X-ray tomography system.

The ASA can be easily mounted in most commercially available tomography systems, either statically or on a rotating platen which allows full rotational tomography. A typical experiment might consist of deforming the sample material up to a predefined strain level using displacement mode. This strain can then be maintained constantly throughout the duration of the image acquisition cycle and any load change recorded by the load cell (effectively a stress relaxation experiment). It should be noted that a high resolution 3D rotational tomography image may take 10 hours or more to complete, so the inherently high structural rigidity of the ASA is particularly useful in maintaining stability throughout the image acquisition cycle.

The choice of indenter material is also important because a large X-ray absorption mismatch between the indenter material and the sample material can affect the contrast of the resultant image. The indenter also has to be tailored to the size scale of the material being investigated.

Example of an X-ray tomography measurement made on a polymer foam (5 mm wide, 7 mm high) which has been deformed by a fused silica square (3 x 3 mm) maintained at 10% strain over the 12 hrs of the image acquisition cycle (image resolution of 3 µm)

Alemnis Standard Assembly (ASA) mounted vertically in a Zeiss Xradia 620 Versa X-ray tomography system.

REQUEST A QUOTE

Please fill in the boxes on the contact form and a member of the team will contact you directly for a quotation.

Each quotation will be unique to the customer requirements so please give as much information in the contact form as possible, this will enable us to get the most accurate price back to you.

Selected References

- J. Gamcová, G. Mohanty, Š. Michalik, J. Wehrs, J. Bednarčík, C. Krywka, J. M. Breguet, J. Michler, and H. Franz, Mapping strain fields induced in Zr-based bulk metallic glasses during in-situ nanoindentation by X-ray nanodiffraction, Applied Physics Letters 108 (2016) 031907

- A. Bhowmik, G Sernicola, J Lee, T. B. Britton, W. Liu, T-S Jun, M. Karimpour, D. S. Balint, F. Giuliani, Deformation behaviour of [001] oriented MgO using combined in-situ nano-indentation and micro-Laue diffraction, Acta Materialia 145 (2018) 516-531