Alemnis is often asked about the relevance of micromechanical testing to macroscale properties. In fundamental research, the downsizing of material volumes to be tested allows to probe the intrinsic deformation behaviour of materials. Beyond fundamental research, micromechanical testing helps to inform large scale models with the properties of individual constituent phases and their mutual interfaces. Here we compile a few excellent examples from the literature, where micromechanical testing has played a crucial role in solving macroscale challenges encountered in a wide variety of scientific disciplines.

Bridging the Gap From Micro- to Macroscale

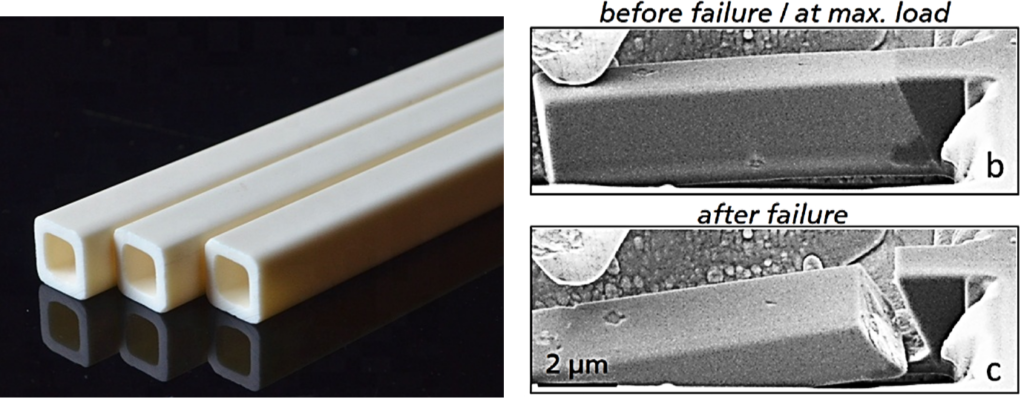

Improving the mechanical performance of ceramics

Mechanical properties of individual grain boundaries dominate fracture toughness and strength in ceramics. Micromechanical experiments are the only way to experimentally investigate such grain-grain interaction and to inform the design of microstructural controls that improve overall mechanical performance.

Ast, J. et al. Open Ceram. 8, (2021).

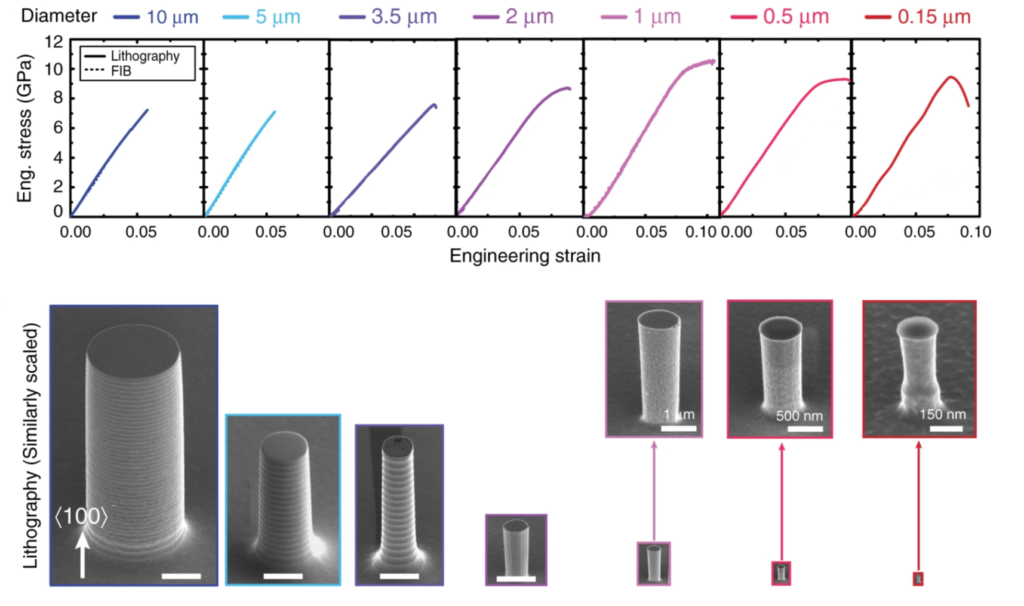

Exploiting size effects of semiconductor materials

The size-dependent mechanical performance of semiconductors is a nano-scale effect, and as such highly relevant for microelectromechanical systems (MEMS). Moreover, increasing elastic strain limits and plasticity can also enhance functional properties of semiconductors because higher elastic strains can modify the band structure.

Chen, M. et al. Nat. Commun. 11, 1–10 (2020).

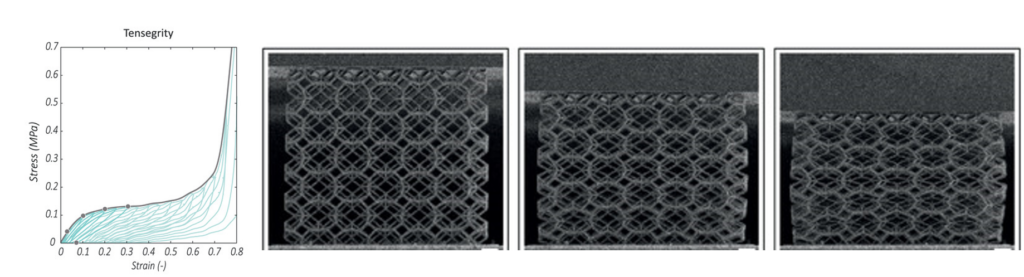

Tailoring architectured microstructures

From porous ceramics to 3D-printed metamaterials, experimental confirmation of the mechanical performance of new light-weight materials remains an important task. By means of micromechanical experiments, one can investigate the mechanical performance of individual struts as well as their collective behaviour.

Bauer, J., et al. Adv. Mater. 33, 1–9 (2021).

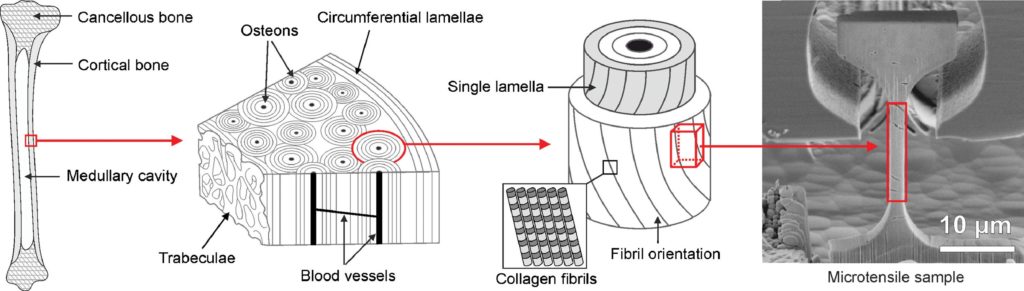

Understanding hierarchical structures

Two prime example of hierarchical materials are bones and composites. Macroscale mechanical properties of such materials are controlled by micromechanical properties of individual constituents such as fibres or fibrils, and their interfaces with a matrix. Moreover, all these sub-levels usually display a strongly anisotropic behaviour. Micromechanical testing is a unique way to deconvolute the overall mechanical behaviour. This is crucial for fundamental understanding and finding pathways to performance increase.

Casari, D., et al. Acta Biomater. 120, 135–145 (2021).

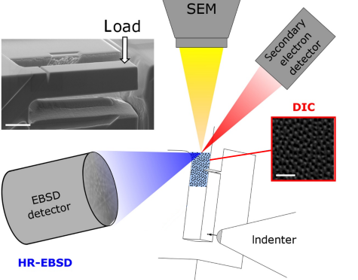

Engineering stronger alloys

The overall strength of metals and alloys is controlled by highly localized strain. In situ micromechanical experiments allows the use of correlative techniques such as electron backscattered diffraction (EBSD) or digital image correlation (DIC), which help understand toughness-inducing plasticity, slip and twinning activities. The ability to measure elastic and plastic components of such localized phenomena is crucial to fully characterize, understand, and engineer structural materials that “bend, not break”.

Edwards, T. E. J., et al. Sci. Adv. 8, 5735 (2022).