The Automated Large Sample Platform (ALSP) uses an ASA fitted with Mini Load Cell (MLC) together with an Extended XYZ Stage (EXYZ) and an Optical Microscope (OPT-MIC). The complete assembly fits inside the Insulating Enclosure (ENC-INS).

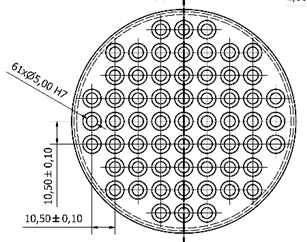

The EXYZ can accommodate samples up to 100 mm in diameter (including semiconductor wafers up to 4 inch diameter) with XY range of 150 mm, Z range of 30 mm, speed up to 15 mm/s and a blocking force of 5 N. The repositioning repeatability is < 500 nm over the entire travel range with a resolution (closed loop) of 1 nm.