- Home

- Alemnis Blog

Blog Articles

Understanding the Different Types of Extreme Conditions Tests

When a material is used for a specific application, an expectation is created around why it has been chosen. These assumptions will be based on the durability of its properties and characteristics. The reliability of materials make all the difference …

Extreme Conditions Testing for Real-World Applications

Materials need to be fashioned to survive even the most harsh of conditions. That way when they are applied in the real-world, they can live up to expectations. You would not want materials obtained for cars to be fragile, the …

What is High Strain Rate Nanoindentation?

High strain rate nanoindentation is a sophisticated materials testing technique. It has emerged as a crucial tool for the mechanical characterization of materials at the nanoscale, particularly in understanding their mechanical properties under rapid deformation. The methodology behind this technique …

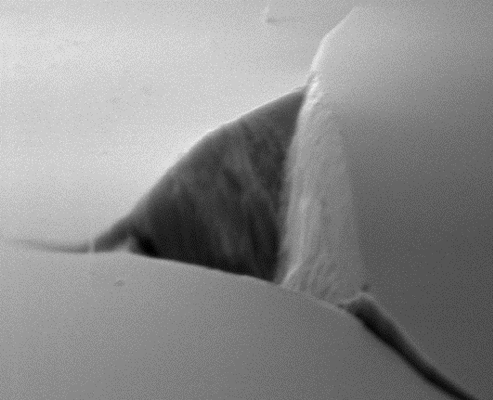

Conducting Surface Integrity Assessments via Scratch Resistance Testing

Scratch resistance testing is a mainstay in materials science. It has become increasingly vital for assessing the mechanical integrity of surfaces; particularly relevant for bulk materials and coatings. It is essential in various fields ranging from thin film analysis to …

Understanding the Effects of Loading Rate in Nanoindentation Testing

Loading rates refer to the speed at which a nanoindenter applies force to a surface. It is instrumental in influencing the material’s mechanical response. Thus, loading rates help reveal time-dependent behaviour under stress. This helps researchers explain properties like elastic …

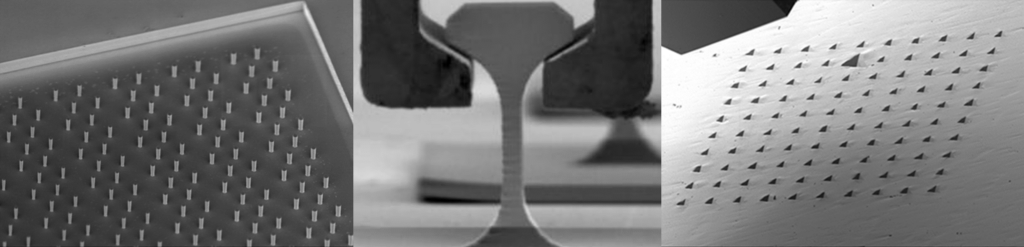

Selecting the Right Nano Indenter Tips

A wide variety of nano indenter tips are available to choose from to assist you with any nanoindentation experiments. Compared to traditional tests, nanoindentation is widely considered the gold standard for testing different surface mechanical properties. It involves using small …

Key Advantages of Real-Time Contact Observation in Nanoindentation

Nanoindentation is a powerful technique for studying material properties at the nanoscale. Capable of measuring a range of metrics, nanoindentation has proven invaluable in fields from machinery engineering and electronics to implantology and agriculture.1 To enhance the effectiveness of nanoindentation, …

Uncovering Small-Scale Fracture Mechanics with Nanoindenters

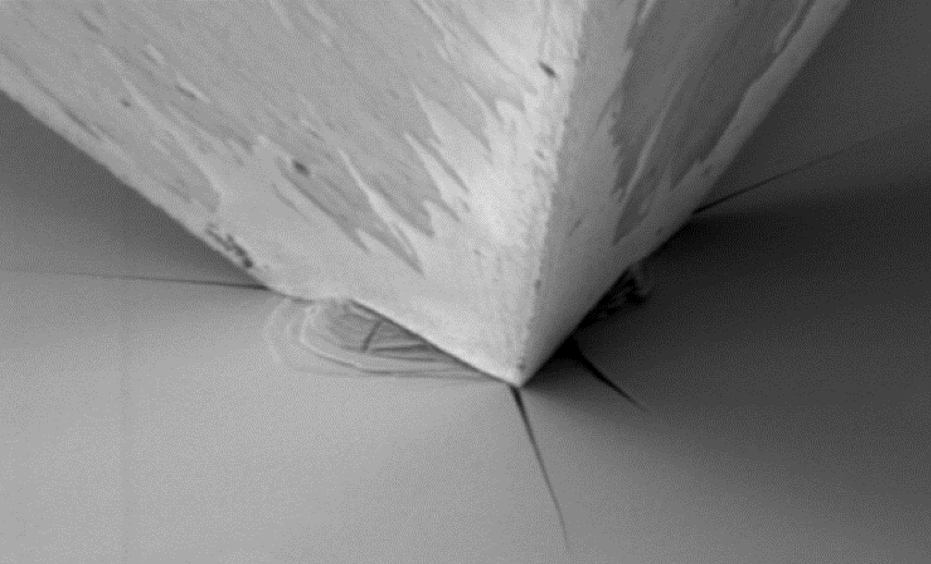

Fracture mechanics is an important branch of materials science that delves into understanding the cracks in materials and how they propagate. This field has been instrumental in predicting material failure, especially in engineering materials subjected to applied stress. As we …

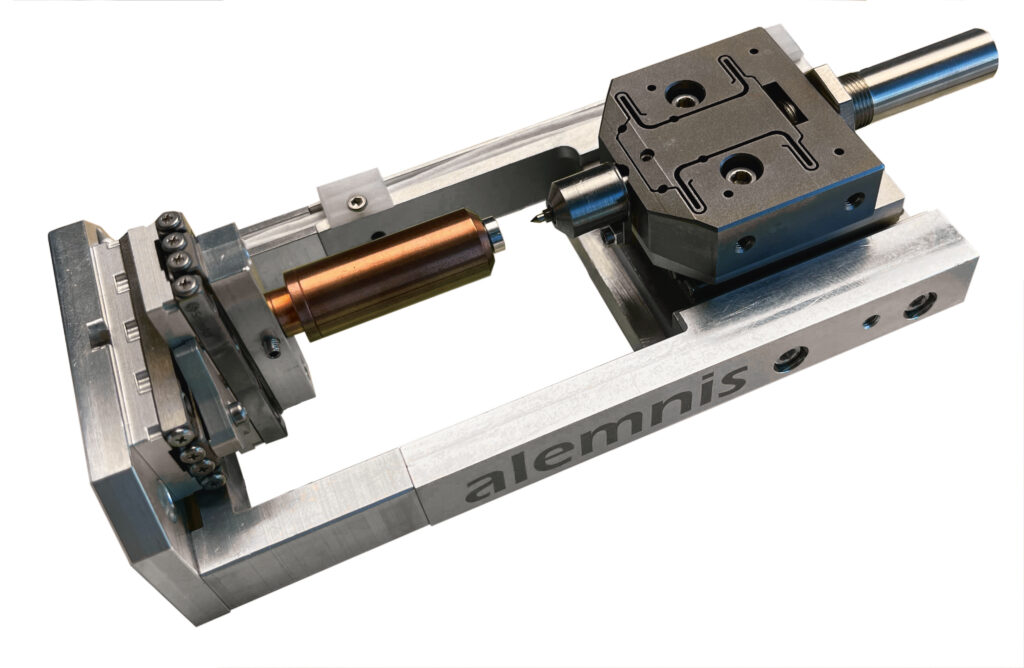

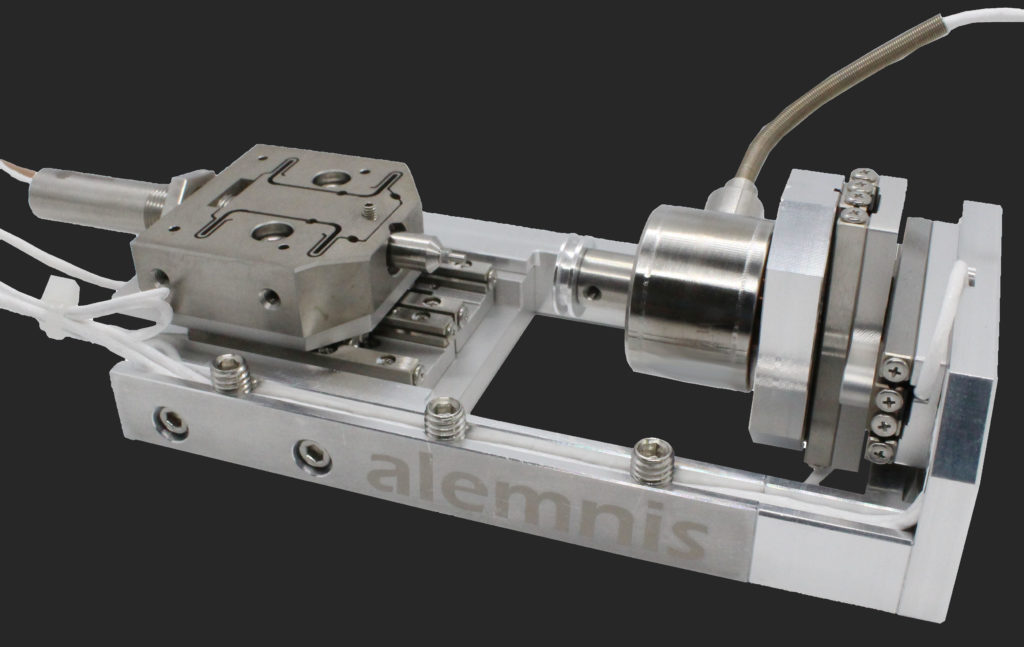

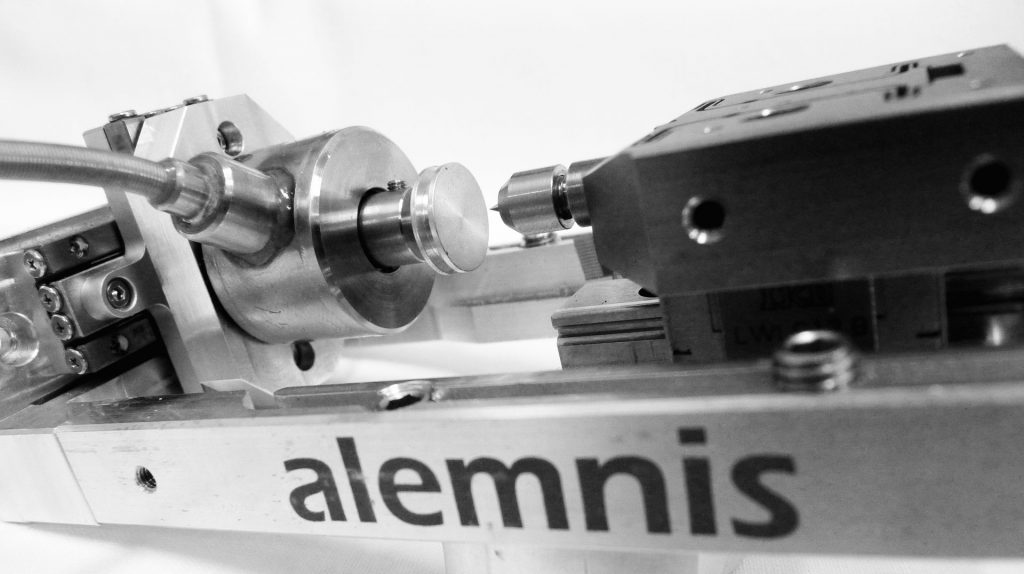

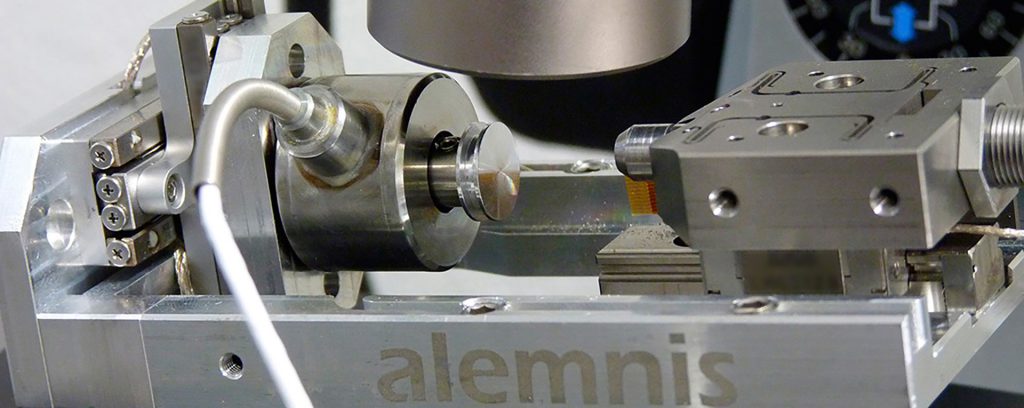

What are the advantages of the Alemnis mini load cell (MLC)?

The mini load cell (MLC) is a specialized device used to measure force or load. Its design and functionality are centered around precision and sensitivity, particularly in dynamically demanding applications. The “mini” aspect refers to its size compared to the …