Nanoindentation is a ubiquitous analytical technique used to investigate a wide range of material properties. With increasingly compact geometries and high-resolution, nanoindenters can explore the mechanical properties of microscale samples to obtain results that are analogous to the macroscale, bulk material. The cost and convenience benefits of this are self-evident.

Nanoindenters can be leveraged in a choice of materials science test methods and applications. They are also increasingly pivotal in preliminary testing that enables further, more detailed mechanical analyses downstream.

Elastic modulus, for instance, is a key property underlying a range of dynamic behavioral mechanics including fracture toughness which is commonly calculated according to the Dukino and Swain equation. In brief, this considers fracture toughness a function of an applied indentation load, average crack length, the ratio of hardness to elastic modulus, and a geometric constant.

In this blog post, Alemnis will briefly explore how nanoindenters can be used to determine the elastic modulus of materials.

What is Elastic Modulus?

First, let us offer a short definition of elastic modulus. Often referred to as Young’s modulus, after British scientist Thomas Young, the elastic modulus of a material is a measure of its ability to resist bending or compressive forces and is consequently connected to both hardness and stiffness. Elastic moduli are determined as the ratio of tensile stress to strain within the material’s elastic limits for compressive and tensile loads; essentially comprising a measure of the force required to cause reversible (elastic) deformation.

Nanoindenters are used to probe materials and measure malleability/brittleness in relation to linear elasticity on a stress-strain graph. This is critical for gaining a thorough understanding of material performance under pre-defined use conditions and forecasting various dynamic deformation mechanics or modes of failure.

How Do Nanoindenters Determine Elastic Modulus?

To measure the elastic moduli of materials, nanoindenters bring a probe tip into contact with the surface at minuscule loads, typically just a few micronewtons (µN). This load is ramped up at user-defined rates to a maximum point and then decreased back down to zero at the same rate. Conventional indentation tests acquire load-displacement curves that are indicative of various mechanical properties. By observing the unloading curve, analysts can observe the elastic recovery of sample materials, which is a fundamental parameter in calculating elastic modulus.

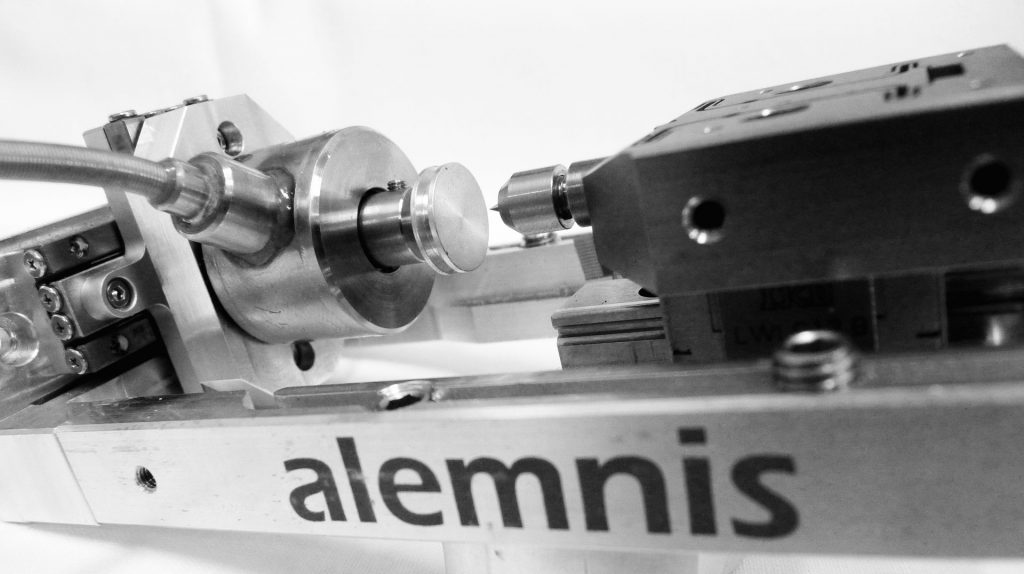

Alemnis Nanoindenters

At Alemnis, we have developed a class-leading nanoindentation unit that pushes the frontiers of nanomechanical testing. The Alemnis Standard Assembly (ASA) exceeds traditional nanoindenters in terms of measurement accuracy and experiment flexibility. If you would like more information about measuring the elastic moduli of your materials with our innovative nanoindenter, simply contact a member of the team today.