Key Advantages of Real-Time Contact Observation in Nanoindentation

Nanoindentation is a powerful technique for studying material properties at the nanoscale. Capable of measuring a range of metrics, nanoindentation has proven invaluable in fields from machinery engineering and electronics to implantology and agriculture.1 To enhance the effectiveness of nanoindentation, real-time contact observation has emerged as a key advancement. This article explores the concept of nanoindentation, highlights its importance, and discusses the advantages that real-time contact observation and high-temperature nanoindentation bring to the field.

Read more: Key Advantages of Real-Time Contact Observation in NanoindentationUnderstanding Nanoindentation

Nanoindentation is a versatile technique used to measure the mechanical properties of materials at the nanoscale. It involves the application of a controlled force on the surface of a material using an indenter, such as a spherical or pointed diamond and measuring the resulting penetration depth.2 The load-displacement data obtained during the process provides valuable insights into the material’s response to mechanical stress, offering a detailed understanding of its mechanical behavior. Properties such as hardness and elastic moduli can be assessed, and viscoelastic properties, fracture toughness and strain-hardening exponents can be derived.3

The Importance of Nanoindentation

In contrast to a microhardness tester, nanoindentation eliminates the need for a powerful microscope to measure the indentation impression. Instead, it relies on the indentation depth and the indenter geometry to determine the contact area. This characteristic makes nanoindentation particularly well-suited for examining nanoscale thin films and materials, as it allows for controlling the indentation depth to minimize substrate effects. These capabilities extend beyond the constraints of micro and macro tests, which can sometimes yield inaccurate measurements or only provide composite values, thereby making them particularly invaluable when dealing with coated materials or heterogeneous substances during testing.4

Advantages of Real-Time Contact Observation

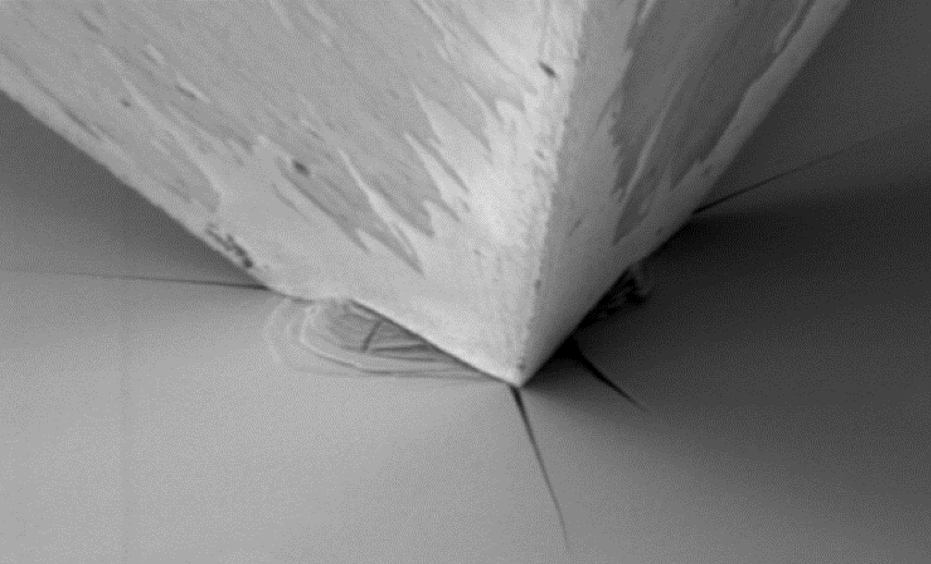

Real-time contact observation takes nanoindentation techniques to new heights. Unlike conventional nanoindentation, the indentation area can be observed directly through an electron microscope allowing for the visualization of the contact area.5,6 This can lead to more reliable and repeatable experimentation. Furthermore, by viewing the indentation process, instantaneous feedback can be gathered on a material’s behavior, such as fracture onset, delamination, and time-sensitive behavior like viscoelasticity. Accordingly, researchers can identify changes in material properties that would otherwise be missed with conventional “post-mortem” analysis.7

Investigating High-Temperature Nanoindentation

High-temperature nanoindentation represents a specialized area within the field of nanoindentation, enabling precise characterization of a material’s mechanical behavior at elevated operational or processing temperatures. This involves subjecting the sample and indenter to temperatures as high as 800 °C, often conducted in a vacuum to prevent undesired atmospheric effects. The technique faces challenges like temperature drift and sample oxidation. However, with advancements like the Alemnis High-Temperature Module (HTM), high-temperature nanoindentation has become a standard method for studying temperature effects on material properties.8

Applications of Nanoindentation: High Temperature and Real-Time Contact Observation

High-temperature nanoindentation opens exciting possibilities for fundamental materials research. Its highly localized nature allows for an in-depth exploration of material behavior kinetics. This technique has been effectively employed to characterize a wide range of temperature-induced material effects, such as phase transitions in semiconductors like Si and Ge,9 stress-strain analysis of P91 steel,10 uncovering the atomic-level mechanisms of plasticity in solids,11,12 and crystallization behavior in bulk metallic glasses.13

High-temperature nanoindentation can also be combined with imaging techniques (e.g., SEM and TEM) and electrical measurements, enabling a comprehensive understanding of material behavior at the nanoscale.14 This has recently been demonstrated in additive manufacturing when investigating the temperature-dependent hardness of near-eutectic Ni-Nb,15 an Ni-based alloy that could be utilized in machinery components exposed to extreme loading conditions.16 Advances in these combined in-situ techniques permit real-time studies of temperature effects on microstructure and the intricate relationships between mechanical, electrical, and thermal phenomena at the nanoscale.[SL1]

Nanoindentation: A Small Measure with a Big Impact

Nanoindentation is a critical technique for understanding material properties at the nanoscale. Integrating real-time contact observation into nanoindentation techniques has significantly enhanced its effectiveness, allowing researchers to gain crucial insights into material behavior at unprecedented detail. With the development of high-temperature nanoindentation, the advantages of real-time observation hold immense promise for a wide range of applications in diverse industries. As research in this field continues to advance, real-time contact observation in nanoindentation will likely play a pivotal role in future materials science and engineering.

References and Further Reading

1. Nemecek J. (2012). Nanoindentation in Materials Science. http://dx.doi.org/10.5772/2829

2. Bhushan B, et al. (2016). Nanoindentation. Encyclopedia of Nanotechnology. https://doi.org/10.1007/978-94-017-9780-1_41

3. Peng Q. (2011). First-Principles Quantum Simulations of Nanoindentation. Nanoindentation in Materials Science. http://dx.doi.org/10.5772/48190

4. Sasmal S, et al. (2019). Nanoindentation for evaluation of properties of cement hydration products [chapter 7]. Nanotechnology in Eco-efficient Construction (Second Edition) Materials, Processes and Applications. https://doi.org/10.1016/B978-0-08-102641-0.00007-4

5. Cohen SR, et al. (2013). Dynamic nanoindentation by instrumented nanoindentation and force microscopy: a comparative review. Beilstein Journal of Nanotechnology. https://doi.org/10.3762/bjnano.4.93

6. Rzepiejewska-Malyska KA, et al. (2008). In situ mechanical observations during nanoindentation inside a high-resolution scanning electron microscope. Journal of Materials Research. https://doi.org/10.1557/JMR.2008.0240

7. Nowak J, et al. (2010). In-situ nanoindentation in the SEM. Materials Today. https://doi.org/10.1016/S1369-7021(10)70144-9

8. Alemnis [Online]. High Temperature Nanoindentation. Available at: https://alemnis.com/high_temperature_nanoindentation/ (Accessed on 27 July 2023)

9. Chavoshi SZ, et al. (2018). Temperature-dependent nanoindentation response of materials. MRS Communications. https://doi.org/10.1557/mrc.2018.19

10. Ruiz Moreno A, et al. (2020). Stress−strain curves and derived mechanical parameters of P91 steel from spherical nanoindentation at a range of temperatures. Materials & Design. https://doi.org/10.1016/j.matdes.2020.108950

11. Schuh CA, et al. (2005). Quantitative insight into dislocation nucleation from high-temperature nanoindentation experiments. Nature Materials. https://doi.org/10.1038/nmat1429

12. Choi I-C, et al. (2017). Thermally activated dislocation plasticity in body-centered cubic chromium studied by high-temperature nanoindentation. Acta Materialia. https://doi.org/10.1016/j.actamat.2017.08.026

13. Nieh TG, et al. (2004). Comparative studies of crystallization of a bulk Zr–Al–Ti–Cu–Ni amorphous alloy. Intermetallics. https://doi.org/10.1016/j.intermet.2004.04.011

14. Nili H, et al. (2013). In situ nanoindentation: Probing nanoscale multifunctionality. Progress in Materials Science. http://dx.doi.org/10.1016/j.pmatsci.2012.08.001

15. Jones MR, et al. (2023). Evidence of twinning-induced plasticity (TWIP) and ultrahigh hardness in additively-manufactured near-eutectic Ni–Nb. Journal of Material Science. https://doi.org/10.1007/s10853-023-08636-8

16. Vijay Reddy K, et al. (2020). Effect of Ni–Nb Metallic Glass on Moderating the Shock Damage in Crystalline Ni-Amorphous Ni62Nb38 Nanocomposite Structure: A Molecular Dynamics Study. In: TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings. The Minerals, Metals & Materials Series. https://doi.org/10.1007/978-3-030-36296-6_85