SCRATCH TESTING

The basic principle of the scratch test is that an indenter of known geometry (commonly a spherical diamond) is dragged across a surface with either constant or progressive loading. In the case of coatings, a progressive load is usually used for generating an increasing stress until failure events occur at specific points along the scratch track, such critical failure points (or critical loads, Lc) being observed by subsequent optical microscopy, variations in frictional force, acoustic emission or changes in penetration depth.

Not all the observed failure events in a progressive load scratch test are related to delamination at the coating-substrate interface and only certain, therefore, can be truly used as a measure of adhesion. Other types of failure, such as cohesive damage within the coating or substrate, may be equally important in evaluating the in-service behavior of a coated component in a specific application. In many cases, the scratch test has now become accepted as a versatile tool for assessing the mechanical integrity of a surface, whether bulk or coated, and has found application in many different fields of materials research and industrial R&D. In general, it is most effective if the substrate does not deform plastically to any great extent. In such cases the coating is scraped off the surface and the load required to do this gives some measure of adhesion, although it is not a simple analysis and therefore a quantitative number is difficult to obtain. For coating-substrate systems that have different friction coefficients, it is often possible to detect a frictional force change when the indenter penetrates through the coating and arrives at the substrate.

The Alemnis Standard Assembly (ASA) can be used for scratch testing in various different configurations and has the advantage of in situ SEM observation of the scratch as it develops in real time. This is particularly useful for understanding scratch deformation phenomena, such as whether cracking is occurring in front of the advancing indenter by compression, or behind the indenter by tension. It is also possible to directly observe any viscoelastic relaxation that might occur in the deformed material immediately after load removal.

The ASA can be used in several different ways to scratch surfaces. Here are some typical examples:

1) Scratch Tests on paper

One of the distinct advantages of true displacement mode is that the indenter displacement can be controlled in either displacement or load control over the duration of the scratch test. This can be particularly interesting in soft materials where load control may cause sinking of the indenter into the material and so displacement control is advantageous.

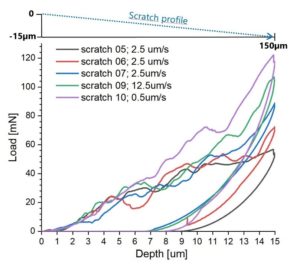

Example of 5 scratches made in a polymer-coated paper sheet with a conical diamond indenter of radius 1 µm in depth control with linear displacement up to a maximum of 15 µm

Example of a displacement controlled scratch into a polymer-coated paper sheet with a conical diamond indenter of radius 1 µm

2) Scratch testing to simulate chipping of hard coatings

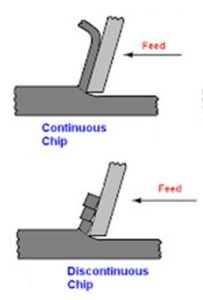

Scratch testing is commonly used for investigating the integrity of thin films and coatings by measuring the scratch resistance, viscoelastic recovery and onset of cracking. It can also be used to simulate the action of a cutting tool (e.g., drill bit, milling bit, cutter) as it deforms the surface and produces a chip. The observation of chipping in-situ in the SEM allows one to understand the chipping mechanism in more detail.

Example of chipping mechanisms in Zr/Zr2N multilayers deposited on a metallic substrate. The indenter is of diamond with a radius of 100 µm (From Ref. 4)

Selected References

- R. Rabe, J-M Breguet, P. Schwaller, S. Stauss, F. J. Haug, J. Patscheider and J. Michler, Observation of fracture and plastic deformation during indentation and scratching inside the scanning electron microscope, Thin Solid Films 469-470 (2004) 206-213

- J. Michler, R. Rabe, J. L. Bucaille, B. Moser, P. Schwaller and J-M Breguet, Investigation of wear mechanisms through in situ observation during microscratching inside the scanning electron microscope, Wear 259 (2005) 18-26

- Wasmer K., Pouvreau C., Giovanola J., Michler J. (2006) Scratching and Brittle Fracture of Semiconductor In-Situ Scanning Electron Microscope. In: Gdoutos E.E. (eds) Fracture of Nano and Engineering Materials and Structures. Springer, Dordrecht

- L. Major, R. Major, M. Kot, J. M. Lackner and B. Major, Ex situ and in situ nanoscale wear mechanisms characterization of Zr/ZrxN tribological coatings, Wear 404-405 (2018) 82-91

- L. Major, J. Lackner, M. Kot, B. Majora, Nanostructural aspects of the wear process of multilayer tribological coatings, Tribology International 151 (2020) 106411 https://doi.org/10.1016/j.

triboint.2020.106411