TENSILE TESTING

The strength of a material under tension has long been regarded as one of the most important characteristics required for design, prototyping, production and lifetime prediction. Macroscale tensile testing of bulk materials is still one of the most common techniques for measuring their yield stress, elastic modulus, ultimate tensile strength and fracture strength. For microscale properties, the challenge has always been how to machine very small tensile samples accurately and reproducibly, how to grip such samples and is there a suitable testing instrument with sufficient resolution.

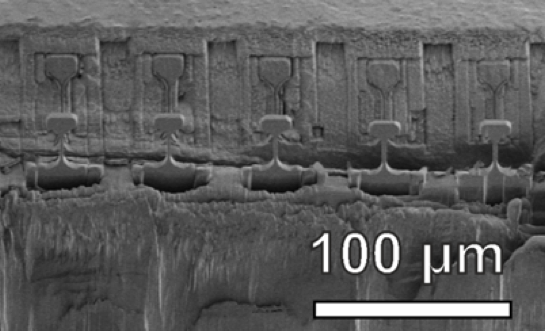

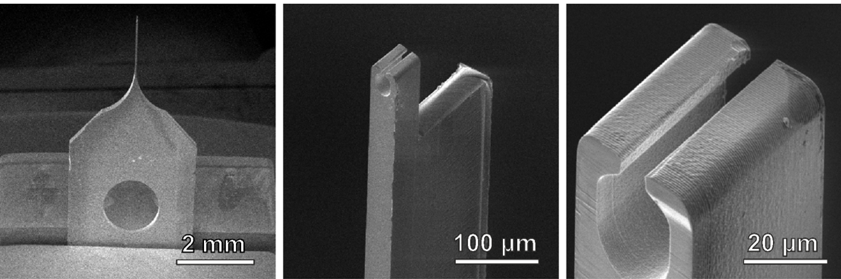

Example of nanocrystalline Ni tensile dog-bone samples

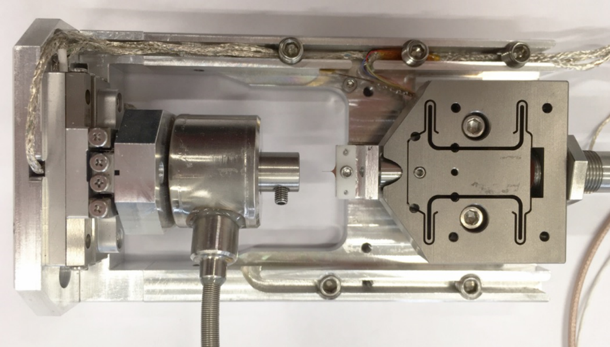

The machining of very small tensile dog-bone samples has been solved by either milling them using a Focused Ion beam (FIB) or by etching them out of bulk material by lithographic techniques. The gripping issue has been solved by the development of dedicated microscale grippers which can perfectly match the geometry of the dog-bone shoulders. The instrumentation issue has been solved by using an Alemnis Standard Assembly (ASA) for performing tensile testing.

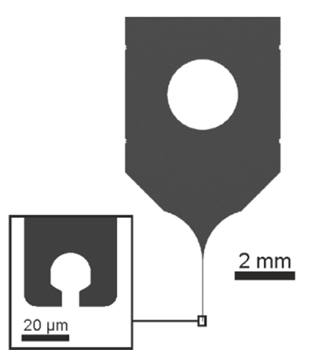

Detail of the tensile gripper design and mounted on the Alemnis Standard Assembly

If the alignment of the pulling head of the machine does not coincide with the symmetry axis of the test specimen, the desired uniform stress application will be corrupted by an imposed bending stress. This will have several effects – false indication of elastic modulus, suppression of upper yield phenomena and decrease in the indications of limit of proportionality, apparent lower-yield strength or proof strength. The alignment issue has been solved in the Alemnis system by matching the radius of the gripper shoulder to the radius of the dog-bone sample. In this way, a slight misalignment between them will be automatically compensated by a small deflection of the gripper arm which has a certain elasticity and can therefore conform to the ideal position, giving an incentive for self-alignment in most cases. Finite Element Analysis (FEA) has shown that any error in the yield strain is significantly reduced compared to a more rigid design.

Focused ion beam (FIB) was used to produce microtensile specimens to mimic ASTM 638 tensile specimen stress conditions. Single crystal Si and GaAs specimens were tested to validate the tensile setup. Casari et al., European FIB Network, Grenoble, 2018

Although the displacement is accurately monitored by the ASA throughout the test, it is also possible to apply nano-speckles to the dog-bone by electron beam deposition of metals (e.g., platinum). The resultant array of small dots can be then used for Digital Image Correlation (DIC) of images acquired during the tensile test, allowing the overall displacement field to be monitored.

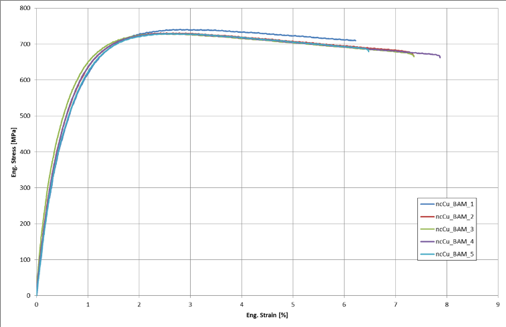

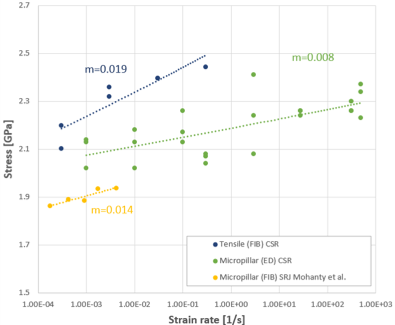

Typical stress-strain curves and comparison of yield stress as a function of strain rate for nanocrystalline Ni tested by tensile testing and by micropillar compression (from Mohanty et al., Phil. Mag. 95:16-18, pp. 1878-1895, 2016)

Selected References

- G. Mohanty, J. M. Wheeler, R. Raghavan, J. Wehrs, M. Hasegawa, S. Mischler, L. Philippe, J. Michler, Elevated temperature, strain rate jump microcompression of nanocrystalline nickel, Philos. Mag., Vol. 95, 16-18 (2015) 1878-1895

- F. Di Gioacchino and W. J. Clegg, Mapping deformation in small scale testing, Acta Materialia 78 (2014) 103-113

- D. Casari, L. Pethö, P. Schürch, X. Maeder, L. Philippe, J. Michler, P. Zysset, J. Schwiedrzik, A self-aligning microtensile setup: Application to single-crystal GaAs microscale tension–compression asymmetry, Journal of Materials Research, 1-18. (2019) https://doi.org/10.1557/jmr.2019.183

- N.M. della Ventura, S. Kalacska, D. Casari, T. E. J. Edwards, A. Sharma, J. Michler, R. Logé, X. Maeder,Twinning mechanism during in situ micro-tensile loading of pure Mg: role of basal slip and twin-twin boundary interaction, Acta Materialia, (2020) http://dx.doi.org/10.2139/ssrn.3628969

- D. Casari, J. Michler, P. Zysset, J. Schwiedrzik, Microtensile properties and failure mechanisms of cortical bone at the lamellar level, Acta Biomaterialia, (2020) https://doi.org/10.1016/j.actbio.2020.04.030