What is Stress Relaxation of Materials?

Understanding stress relaxation is essential for ensuring the long-term integrity and reliability of various materials under different conditions and is crucial for those designing structural applications. In this blog post, we look at the concept of stress relaxation, its occurrence in viscoelastic materials, and its importance in the design and application of materials.

Stress Relaxation: Definition and Phenomenon

Stress relaxation is the gradual reduction in stress over time while maintaining a constant strain. It is commonly observed in viscoelastic materials, particularly polymers, which show time-dependent relaxation when subjected to stress or strain. When a stress relaxation experiment is conducted, a sample is rapidly strained to a fixed length at a constant temperature, and the stress is recorded as a function of time. During the experiment, the length of the sample remains constant, allowing stress relaxation to occur at a molecular level through molecular relaxation and viscous flow.

Stress Relaxation vs. Creep

It is important to differentiate stress relaxation from creep, as they are distinct phenomena. Creep involves the constant application of stress while adding an increasing amount of strain. Creep experiments are conducted by subjecting a material to a constant stress and recording the resulting strain over time. In contrast, stress relaxation experiments involve applying a constant strain and monitoring the stress response over time. These differing experimental setups highlight the unique characteristics of stress relaxation and creep in materials.

Factors Influencing Stress Relaxation

Various factors influence the rate of stress relaxation in polymers, including the type of polymer, the presence of fillers, strain levels, strain rates, and temperature. Additionally, the polymer’s stress relaxation behavior can be significantly impacted by the nature and composition of the polymer.

It’s also important to know that the stress relaxation rate depends on the strain levels and strain rates applied to the material. Higher strain levels and faster strain rates typically lead to more rapid stress relaxation. Temperature also plays a vital role in stress relaxation, as higher temperatures generally result in faster relaxation.

Furthermore, external factors alone do not determine stress relaxation as it is also influenced by the intrinsic properties of the material. This includes its alloy, temper, and orientation. Considering these factors is crucial in accurately predicting and designing materials for specific applications.

Importance of Stress Relaxation in Design and Applications

Understanding stress relaxation is paramount when designing and selecting materials for structural applications because prolonged exposure to stress can result in irreversible deformation in plastic materials, compromising their structural integrity.

The data obtained from stress relaxation testing is particularly valuable in failure analysis and predicting material behavior under specific loading conditions. By accounting for stress relaxation, engineers can accurately model and simulate the long-term performance of materials, improving the overall reliability and safety of structural components.

Alemnis: Stress Relaxation Measurement Solutions

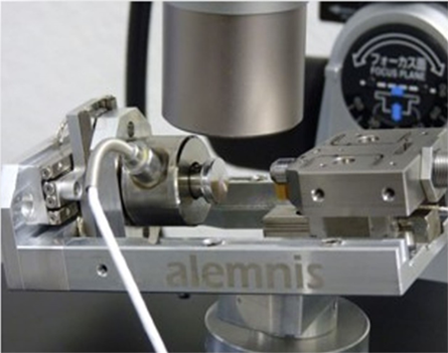

As scientific experts, it is essential to recognize the significance of stress relaxation and its implications in various industries. At Alemnis, we are dedicated to providing leading micro- and nanomechanical property measurement instruments in a range of material science applications.

Our Alemnis Standard Assembly (ASA) is a unique and powerful solution used reliably for stress relaxation measurements. It can be used in in-situ, ex-situ, in synchrotron, and Micro CT configurations in true displacement mode for understanding compression artifacts, load drops, strain rate jumps, and sudden load excursions in real-time.

To ensure your stress relaxation measurements are accurate and reliable, contact Alemnis today, and let us show you the solution.