What are the Different Types of Tensile Gripper Systems?

From the intricate micro gripper to the robust hydraulic grips, tensile gripper systems are paramount to testing a material’s strength. Each type, with its inherent advantages and drawbacks, offers specific capabilities for testing various materials. In this article, we delve into the different types of tensile gripper systems and what makes each unique.

The Art and Science of Gripper Systems

Understanding the role of tensile grips in material testing requires an appreciation for the science behind the process. Microtensile testing is an approach to evaluating the strength of a material under tension. It differs from macroscale testing primarily in the volume of sample material required. A macro test for tensile strength will screen key mechanical properties (yield stress, elastic modulus, etc.) of bulk materials, whereas a microtensile test requires specially fabricated tensile samples with sub-millimetre geometries. Naturally, conventional gripper systems like manual vises, pneumatic grips, or hydraulic grips aren’t compatible with such tiny specimens.

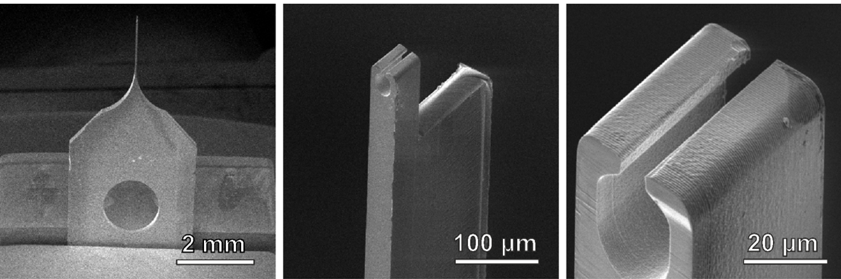

Fabricating reproducible tensile samples at such small scales is an ongoing challenge – as is the issue of how to grip those samples during tensile testing. Microscale gripper systems have emerged as the ideal solution for grasping and manipulating microscale specimens in a range of fields. They can be purpose-built for specific applications, such as high-temperature tensile testing, where thermally-resistant diamond blanks can be cut to size and shape using focused ion beam (FIB) milling. Other applications are routine enough that grippers with a suitable gauge diameter range may be fit for purpose.

Gripping the sample solves part of the issue, but manipulating the sample to accommodate test conditions requires some form of compatible alignment system. Piezo-driven x- and y axes are typically used to position the samples below the grippers. Ideally, the gripper system will be combined with a precise rotation stage used to orient the sample.. A piezo actuator offers displacement from 20 – 100 µm in tensile direction.

Alemnis Gripper Kit: Precision and Versatility

The Alemnis gripper kit is an innovative solution for tensile testing, allowing for meticulous tensile tests on mushroom-shaped pillars. The kit, equipped with an adapter to fit the gripper on the indenter and five standard grippers, is primed for precise application. Its silicon gripper, just 200 µm thick, is designed to grip samples with a gauge diameter of 1 – 15 µm and a mushroom diameter of up to 36 µm. Thanks to its meticulous design, it can accommodate misalignments up to 1° and 0.5 µm, keeping stress deviation within the sample below 10%.

Harnessing the Power of Customization

Flexibility defines the future of tensile gripper systems. As a testament to this, we offer additional grippers as separate items and field requests for customized grippers. This forward-thinking approach underscores the importance of tailoring gripper systems to meet specific needs, advancing the field of material testing.

Ready to Upgrade Your Testing Capabilities?

With a commitment to precision, versatility, and customization, we are poised to provide you with a solution that fits your specific needs. Choose from our range of standard or customized grippers and bring your material testing to the next level. Contact us today to learn more about how our gripper systems can revolutionize your testing process.