Fatigue vs. Creep Testing: What’s the Difference?

Creep testing and fatigue testing are two highly regarded methods used to assess the behavior of materials under varying loading conditions. Creep testing measures the gradual rate of deformation of a material under constant load and temperature conditions. Fatigue testing, on the other hand, involves subjecting a material or structure to cyclic loading. Experts must understand how these two methods are different, as they are necessary for evaluating the long-term performance and reliability of materials in various industries. In this blog post, we will look into the differences between fatigue testing and creep testing, including their underlying principles, testing procedures, and failure mechanisms.

Fatigue Testing

Fatigue testing is a method of mechanical testing conducted by adding cyclic loading to a structure. This method generates data on fatigue life and cracks, identifies critical areas, and assesses the safety of structures prone to fatigue. Fatigue occurs when a material undergoes fluctuating stresses and strains, eventually leading to cracks or a complete fracture. Fatigue tests aim to simulate real-world conditions and predict the material’s endurance under repetitive loading cycles. This method is common in the transport industry for testing components manufactured for automobiles and aircraft, as well as in the medical industry for testing implant materials.

Creep Testing

Creep testing assesses the progressive deformation of a material under constant load and temperature conditions. Creep is the tendency of materials to deform when subjected to long-term stress, especially at elevated temperatures. To perform a creep test, a constant stress is applied while maintaining a constant temperature. The corresponding strain is then recorded over time. Creep testing is crucial for understanding material behavior in high-temperature applications like jet engines and power plants.

Distinguishing Factors

The primary difference between fatigue and creep testing lies in the type of loading and the failure mechanisms involved. Fatigue testing looks at cyclic loading and how cracks or fractures are likely to develop due to fluctuating stresses and strains. In contrast, creep testing focuses on the material’s deformation under constant load and temperature conditions over extended periods. While both methods assess material performance, they address different aspects of long-term durability and reliability.

What is Creep Fatigue?

The term ‘creep fatigue’ often appears when discussing fatigue or creep testing. Creep fatigue, which involves crack elongation over time, may occur when materials are subjected to stress and extreme temperatures. It is important to note that surface finish and heat treatment factors can significantly impact fatigue life.

How is Creep Fatigue Tested?

To test for metal creep or fatigue, specialized procedures are employed. However, the earliest stages of creep are not visible to the naked eye and occur on a molecular level. Creep-to-fail testing is the most reliable method to determine the long-term performance of products with metal components. Different testing techniques can be utilized, such as flexural and compression creep tests. One commonly employed method is the tensile creep test.

Fatigue testing and creep testing serve different purposes in evaluating material behavior under specific loading conditions. While fatigue testing focuses on cyclic loading and crack propagation, creep testing assesses the deformation of materials under constant load and temperature conditions. Both testing methods are indispensable for comprehending the long-term performance and reliability of materials in diverse applications. By employing appropriate testing techniques, manufacturers can ensure the integrity of their products and meet the demands of various industries.

Alemnis: Providing Mechanical Testing Instruments

Alemnis is a pioneering company that empowers groundbreaking academic research in material science through its state-of-the-art micro- and nanomechanical property measurement instruments. Our cutting-edge products are designed to meet the diverse testing needs of researchers in various environments.

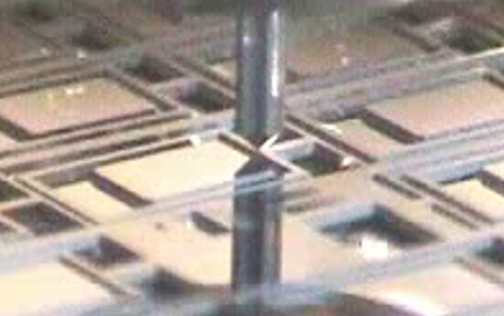

Our flagship product, the Alemnis Standard Assembly (ASA), offers superior accuracy and flexibility for both in-situ and ex-situ nanomechanical testing. This system is an ideal solution for long-term creep experiments, such as for example for holding constant loads for several hours throughout X-ray diffraction studies due to its high stability.

Contact a member of Alemnis today to learn more about fatigue and creep testing.