How an Alemnis Standard Assembly Enhances Tribology Testing

Tribology stands at the intersection of science and engineering. It covers the intricate study of friction, wear, and lubrication, profoundly influencing the performance and longevity of mechanical components. Laboratories dedicated to tribology testing delve deep, extracting pivotal data on friction, lubrication, wear, and surface interactions, thereby shedding light on the failure mechanisms of these components. Given the empirical nature of tribology research, influenced by a myriad of parameters, it’s no surprise that comprehensive testing methods, from field tests to model tests, are employed. As we strive to optimize system performance and reduce maintenance costs, understanding these tribological characteristics becomes paramount.

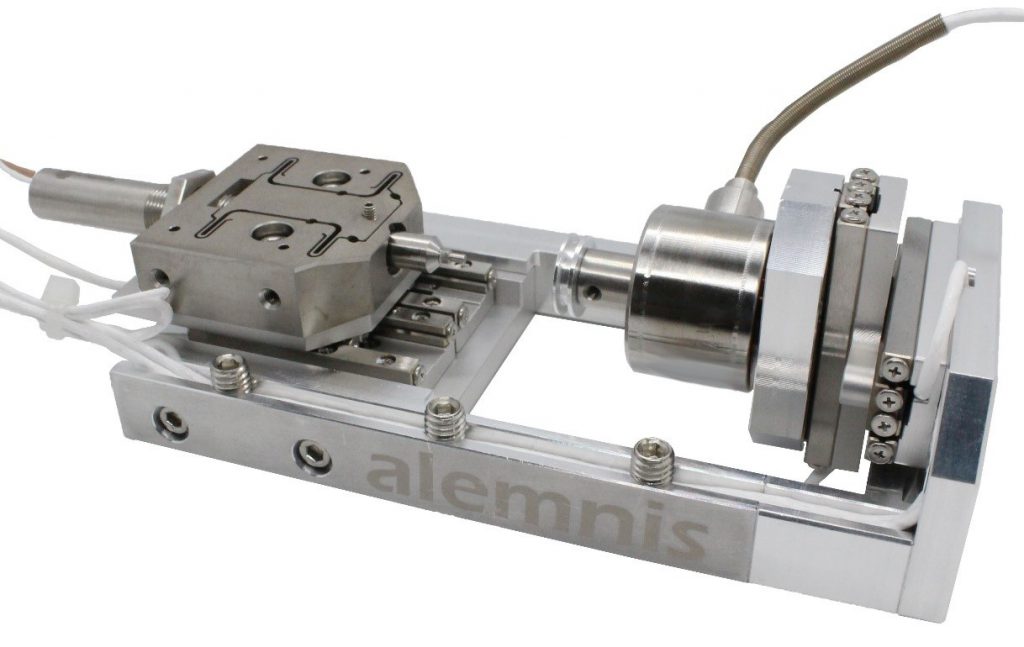

Read more: How an Alemnis Standard Assembly Enhances Tribology TestingEnter the Alemnis Standard Assembly (ASA) – a groundbreaking tool set to redefine the paradigms of tribology testing. Dive in to discover how the ASA is revolutionizing this critical domain.

Versatility in Application

The ASA’s design allows for adaptability in various testing configurations. Whether it’s scratch testing, pin-on-disk testing, or investigating the friction force between two dissimilar materials, the ASA can be tailored to suit the specific requirements of the application. Such versatility ensures that researchers and technicians can optimize the device for their unique testing needs, enhancing the depth and breadth of their investigations.

Automated Precision and Ultra-High Strain Rates

Automation is at the heart of the ASA, making it a fully automated test platform that zeroes in on the mechanical properties of highly localized areas. This precision is further augmented by the ASA’s ability to achieve ultra-high strain rates up to 10,000 s-1. Covering a staggering 8 orders of magnitude, this feature allows for a comprehensive understanding of materials under various dynamic conditions.

Deformation Mechanisms Unveiled

The ASA’s prowess doesn’t end with mere testing. It also delves into the deformation mechanisms of materials. By integrating micro- and nano CT solutions, the ASA offers a unique perspective into how materials deform. Such insights are invaluable, especially when studying materials like polymers coatings, which have complex deformation patterns. Moreover, the acoustic emission data gathered during testing can shed light on the intricate processes occurring within the material.

The Future of Tribology Testing with ASA

In the ever-evolving field of tribology testing, the Alemnis Standard Assembly stands out as a beacon of innovation. Its ability to test fragile materials without damage, its adaptability to various testing methods, and its insights into deformation mechanisms make it an indispensable tool for researchers and technicians alike.

At Alemnis, we are proud to be at the forefront of this revolution. We invite you to explore the myriad possibilities the ASA offers and join us in shaping the future of tribology testing.