A nanoindenter is a versatile instrument used to test the mechanical properties of materials. Primarily developed for localized hardness testing, nanoindentation is now widely used to measure creep, fracture toughness, elastic modulus, stress relaxation, cracking, di slocation nucleation, and the viscoelastic properties of samples.

In this blog post, Alemnis explores the working principles of nanonindenters in more detail.

Nanoindenter Working Principles

At the heart of a nanoindenter is a small probe loaded with a calibrated indenter tip, which may be pyramidal, flat, spherical, wedged, or some other shape. This is used to interrogate the surface of a material and measure the subsequent force-displacement data.

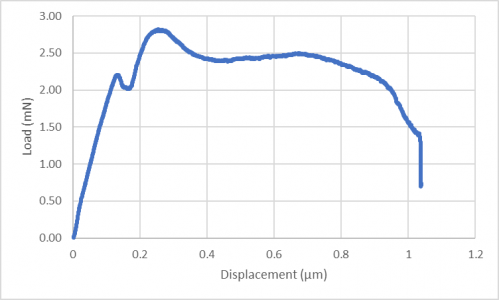

Conventional nanoindenters are typically load-controlled instruments where the tip is brought into contact with the surface under a pre-defined load. Once the nanoindenter has contacted the sample, the load is increased and the tip indents into the material. The area of contact between the tip and the sample, the applied force of the nanoindenter, and the depth of displacement are subsequently used to determine the material’s mechanical properties. The disadvantages of a load-controlled system become obvious when doing compression tests on small structures (e.g., micropillars, 3D structures, etc.) where the load feedback loop cannot cope with sudden displacement excursions. In such cases, nanoindentation measurements using displacement control are far superior.

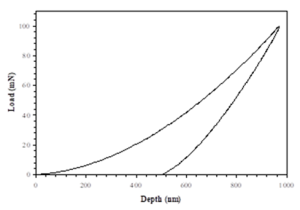

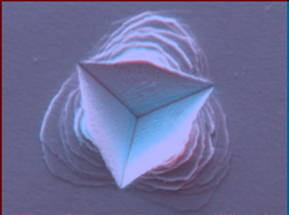

Traditionally, the size and depth of the residual indentation imprint is taken to calculate the material hardness. This is characterized according to one of several indentation hardness scales, including the Vickers and Brinell scales. Nanoindenters have proven valuable for microhardness testing where samples are small or thin, and they have also demonstrated unique performance for measurements where the microstructural properties of a sample are complex or are non-homogenous.

Typical example of a nanoindentation load-depth curve (left) and corresponding residual indent (right)

Applications of Nanoindentation Testing

Nanoindenters are broadly used to test the properties of hard coatings and thin films. As the dimensions of engineering and electronic components continue to decrease, it is vital that local mechanical properties are tested with very little residual impressions. Conventional techniques are largely incapable of testing small-scale components non-destructively, and in best case scenarios may impact the material properties of miniaturized components. Nanoindentation is subsequently used to characterize a range of materials to assist in research and development of new products and solutions. In the case of coatings, a nanoindenter can test the properties of even very thin films (e.g., thickness < 1 µm) without any influence from the properties of the substrate underneath.

Increasingly, nanoindentation has been used to test the complex properties of more dynamic material types including soft, hard, inorganic, and organic samples.

The Alemnis system is fully compatible for in-situ scanning electron microscopy (SEM) experiments, and ex-situ testing with Synchrotron beamlines and standard optical microscopes. This provides new levels of flexibility for dynamic material testing under high strain rates ( up to 10’000 s-1 ) and over very wide temperature ranges (from -150°C up to 1000°C)

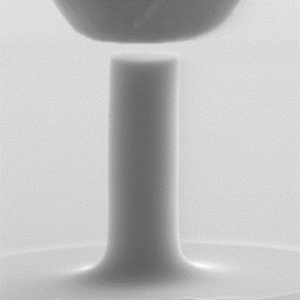

Example of micropillar compression experiment with a flat punch diamond indenter

Localized mechanical testing of materials using the Alemnis system can provide new ways of understanding product failure under end-use conditions. It can be used to measure very small volumes of a specific material which can be in the form of a micropillar fabricated by focused ion beam (FIB) milling or by lithographic techniques such as LIGA. Small volume testing can help to understand the fundamental deformation mechanisms and if performed in-situ allows direct observation of the resultant phenomena, e.g. twinning or slip in metals, stress relaxation in ceramics or creep of oxide structures.

This level of precision has also been explored in the world of emerging biomaterials, offering new understandings of how tissues behave at a cellular level and how this behaviour can be modified. Quantitatively measuring the mechanical properties of biomaterials could provide new insights into biological behaviours, supporting research into innovative pharmaceuticals and medical devices. The Alemnis system can be used to do ex-situ bio-testing in various environments, such as controlled relative humidity, temperature or in liquids (e.g., saline or body-mimicking fluid).

The Unique Alemnis Solution

Alemnis is a specialist in small-scale mechanical testing for materials science research, with a nanoindentation system which can be used in either compression or tension modes. This means that a pillar can be compressed with a flat punch, a surface can be indented with a sharp indenter, or a microscale dogbone sample can be tensile tested, all with the same system. Such high versatility is unmatched and based on years of combined experience.

Read More: What Properties Can Be Measured by Nanoindentation?

The Alemnis system features a true displacement mode as well as various ultra-high strain rate options which permit strain rate jump tests, fatigue testing and dynamic mechanical analysis (DMA). Coupled with the latest state-of-the-art electronics and environmental control, the Alemnis system offers more versatility than any other.

If you would like to learn more about our nanoindenter systems, please do not hesitate to contact us directly.