How are Micropillars Produced?

Micropillar compression testing is a novel materials characterization technique that has emerged as a supplementary – and, in some instances, replacement – technology to indentation testing. Comparable to nanoindentation in terms of its ability to accurately quantify various mechanical properties of materials on the microscale, micropillar compression testing is a valuable addition to the technological arsenals of researchers concerned with myriad different sample types.

The underlying principles of these two techniques are similar, to the extent that near-identical instrumentation can be used to carry out both nanoindentation and micropillar compression tests. This has been demonstrated with materials as varied as metallic alloys, polymeric fibers, and refractory ceramics. The main advantage of micropillar compression over conventional nanoindentation is that the flat punch indenter maintains a constant contact area throughout the experiment so errors in area function are removed from the calculation of mechanical properties.

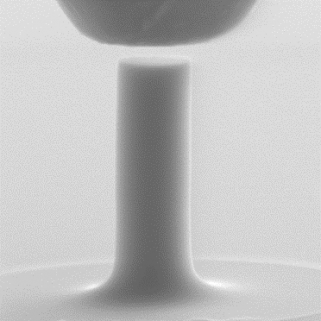

Example of a micropillar compression test on a micropillar built from a multilayer stack of different coatings

Outlining Micropillar Compression Testing

In a typical micro-compression test, a micrometer-scale (μm) pillar of sample material is compressed in a nanoindenter with a calibrated flat punch probe rather than a tip with a pyramidal geometry. Due to the extremely small dimensions of the micropillar, it is desirable to perform in situ positioning of the probe tip within the chamber of a scanning electron microscope (SEM). This eliminates errors associated with poor tip-optic calibration in ex situ testing conditions – yet it is not always appropriate to measure the deformation characteristics of materials in an SEM chamber. Certain polymers, for example, cannot be tested in the vacuum conditions of an SEM due to the potential for beam damage and cracking. In such instances, micropillar compression tests can be conducted in air under an optical microscope.

Each of these test methodologies can provide accurate insights into the real-world stress-strain properties of materials, including extremely complex behaviors like elastic moduli and microscale spatial variation of fracture toughness. Before these tests can be conducted, however, micropillars must be extracted from the bulk material.

Micropillar Fabrication

The primary method used to produce micropillars from bulk materials is focused ion beam (FIB) milling; a technology that mirrors the apparatus of a standard SEM array. Instead of a focussed beam of electrons, FIB setups utilize a high-energy gallium (Ga) ion beam to sputter the uppermost atomic layers of a material and facilitate ultra-precise sample machining on the sub-microscale. This process has become popularised in recent decades due to its outstanding accuracy in semiconductor etching applications.

Surface damage and implantation is a side-effect of FIB milling that could introduce measurement inaccuracies to micropillar compression tests. While gallium ion sources at high ion currents are desired for their superior top-down material removal rates, it may be necessary to ramp down the ion current during processing to optimize the structural and surface finish properties of the micropillar. This improves the yield of microscale samples with mechanical properties representative of the bulk material and decreases the likelihood of FIB induced damage that could affect compression results.

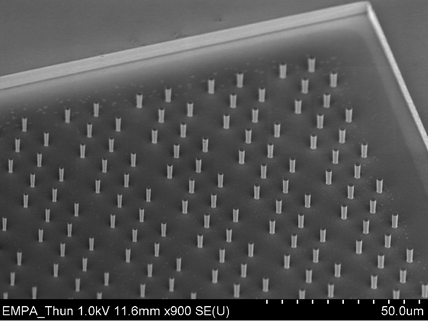

One of the disadvantages of FIB milling is that the micropillar in some materials may not have the same diameter over its whole length. An alternative is to fabricate micropillars from lithographic techniques where material is etched away after creating a surface mask. The advantage of lithographic techniques is that large arrays of micropillars can be fabricated in a few simple steps and much faster than by FIB milling. The shape of such pillars may also be more uniform. Some casting techniques are also available for producing micropillars, but then are based on the materials deposited rather than the bulk.

Examples of Si micropillar arrays (left) made by lithography and a single micropillar (right) just before contact with a diamond flat punch indenter.

Micropillar Testing with Alemnis

Alemnis specializes in the development of value-added tools and solutions for advanced materials testing studies and applications. Our versatile portfolio of products includes the industry-leading Alemnis Standard Assembly (ASA); a compact and flexible nanoindenter suitable for both nanoindentation testing and micropillar compression experiments.

For further information about performing next-generation materials testing with the Alemnis Nanoindenter, please do not hesitate to contact Alemnis today.