2019

H. S. Iyera, G. Mohanty, K. Stillera, J. Michler, M. Colliander, Microscale fracture of chromia scales, Materialia Vol. 8 (2019) 100465 doi.org/10.1016/j.mtla.2019.100465

2018

Ast, J., et al., Interplay of stresses, plasticity at crack tips and small sample dimensions revealed by in-situ microcantilever tests in tungsten. Materials Science and Engineering: A, 2018. 710: p. 400-412.

Ast, J., et al., The brittle-ductile transition of tungsten single crystals at the micro-scale. Materials & Design, 2018. 152: p. 168-180.

Bhowmik, A., et al., Deformation behaviour of [001] oriented MgO using combined in-situ nano-indentation and micro-Laue diffraction. Acta Materialia, 2018. 145: p. 516-531.

Edwards, T.E.J., et al., Longitudinal twinning in a TiAl alloy at high temperature by in situ microcompression. Acta Materialia, 2018. 148: p. 202-215.

Fanicchia, F., et al., Residual stress and adhesion of thermal spray coatings: Microscopic view by solidification and crystallisation analysis in the epitaxial CoNiCrAlY single splat. Materials & Design, 2018. 153: p. 36-46.

Ferrand, H.L., F. Bouville, and A.R. Studart, Processing of dense bio-inspired ceramics with deliberate microtexture. arXiv preprint arXiv:1807.04378, 2018.

Jones, R., et al., Reduced partitioning of plastic strain for strong and yet ductile precipitate-strengthened alloys. Scientific reports, 2018. 8(1): p. 8698.

Knowles, A.J., et al., Data on a new beta titanium alloy system reinforced with superlattice intermetallic precipitates. Data in brief, 2018. 17: p. 863-869.

Lauener, C., et al., Fracture of Silicon: Influence of rate, positioning accuracy, FIB machining, and elevated temperatures on toughness measured by pillar indentation splitting. Materials & Design, 2018. 142: p. 340-349.

Liao, Z., et al., On the influence of gamma prime upon machining of advanced nickel based superalloy. CIRP Annals, 2018.

Schwiedrzik, J., et al., A new push‐pull sample design for microscale mode 1 fracture toughness measurements under uniaxial tension. Fatigue & Fracture of Engineering Materials & Structures, 2018. 41(5): p. 991-1001.

2017

Wehrs J, Deckarm MJ, Wheeler JM, Maeder X, Birringer R, Mischler S, et al. Elevated temperature, micro-compression transient plasticity tests on nanocrystalline Palladium-Gold: Probing activation parameters at the lower limit of crystallinity. Acta Materialia 2017.

Ast J, Polyakov M, Mohanty G, Michler J, Maeder X. Interplay of stresses, plasticity at crack tips and small sample dimensions revealed by in-situ microcantilever tests in tungsten. Ma-terials Science and Engineering: A 2017.

Ast J, Mohanty G, Guo Y, Michler J, Maeder X. In situ micromechanical testing of tungsten micro-cantilevers using HR-EBSD for the assessment of deformation evolution. Materials & Design 2017;117:265-6.

Best JP, Wehrs J, Maeder X, Zechner J, Wheeler JM, Schär T, et al. Reversible, high temperature softening of plasma-nitrided hot-working steel studied using in situ micro-pillar compression. Materials Science and Engineering: A 2017;680:433-6.

Viat A, Guillonneau G, Fouvry S, Kermouche G, Sao Joao S, Wehrs J, et al. Brittle to ductile transition of tribomaterial in relation to wear response at high temperatures. Wear 2017;392:60-8.

Schwiedrzik J, Ast J, Pethö L, Maeder X, Michler J. A new push‐pull sample design for microscale mode 1 fracture toughness measurements under uniaxial tension. Fatigue & Fracture of Engineering Materials & Structures 2017

Ast, J., et al., In situ micromechanical testing of tungsten micro-cantilevers using HR-EBSD for the assessment of deformation evolution. Materials & Design, 2017. 117: p. 265-266.

Best, J.P., et al., Reversible, high temperature softening of plasma-nitrided hot-working steel studied using in situ micro-pillar compression. Materials Science and Engineering: A, 2017. 680: p. 433-436.

Feilden, E., et al., Micromechanical strength of individual Al2O3 platelets. Scripta Materialia, 2017. 131: p. 55-58.

Keller, L.M., et al., Understanding anisotropic mechanical properties of shales at different length scales: In situ micropillar compression combined with finite element calculations. Journal of Geophysical Research: Solid Earth, 2017. 122(8): p. 5945-5955.

Knowles, A.J., et al., A new beta titanium alloy system reinforced with superlattice intermetallic precipitates. Scripta Materialia, 2017. 140: p. 71-75.

Mastorakos, I.N., et al., The effect of size and composition on the strength and hardening of Cu–Ni/Nb nanoscale metallic composites. Journal of Materials Research, 2017. 32(13): p. 2542-2550.

Sernicola, G., et al., In situ stable crack growth at the micron scale. Nature communications, 2017. 8(1): p. 108.

Viat, A., et al., Brittle to ductile transition of tribomaterial in relation to wear response at high temperatures. Wear, 2017. 392: p. 60-68.

Wehrs, J., et al., Elevated temperature, micro-compression transient plasticity tests on nanocrystalline Palladium-Gold: probing activation parameters at the lower limit of crystallinity. Acta Materialia, 2017. 129: p. 124-137.

Xiao, Y., et al., Investigation of the deformation behavior of aluminum micropillars produced by focused ion beam machining using Ga and Xe ions. Scripta Materialia, 2017. 127: p. 191-194.

Zou, Y., et al., Nanocrystalline high-entropy alloys: a new paradigm in high-temperature strength and stability. Nano letters, 2017. 17(3): p. 1569-1574.

2016

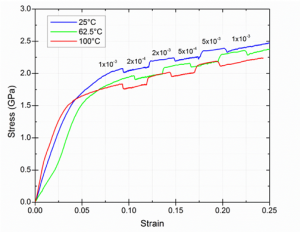

Mohanty G, Wehrs J, Boyce BL, Taylor A, Hasegawa M, Philippe L, et al. Room temperature stress relaxation in nanocrystalline Ni measured by micropillar compression and miniature tension. Journal of Materials Research 2016; 31:1085-95.

Jun T-S, Zhang Z, Sernicola G, Dunne FP, Britton TB. Local strain rate sensitivity of single α phase within a dual-phase Ti alloy. Acta Materialia 2016;107:298-309.

Guo Y, Schwiedrzik J, Michler J, Maeder X. On the nucleation and growth of <1122> twin in commercial purity titanium: In situ investigation of the local stress field and dislocation density distribution. Acta Materialia 2016;120:292-301.

Gamcová J, Mohanty G, Michalik Š, Wehrs J, Bednarčík J, Krywka C, et al. Mapping strain fields induced in Zr-based bulk metallic glasses during in-situ nanoindentation by X-ray nanodiffraction. Applied Physics Letters 2016;108:031907.

Abad OT, Wheeler JM, Michler J, Schneider AS, Arzt E. Temperature-dependent size effects on the strength of Ta and W micropillars. Acta Materialia 2016;103:483-94.

Best JP, Zechner J, Wheeler JM, Schoeppner R, Morstein M, Michler J. Small-scale fracture toughness of ceramic thin films: the effects of specimen geometry, ion beam notching and high temperature on chromium nitride toughness evaluation. Philosophical Magazine 2016;96:3552-69.

Best JP, Zechner J, Shorubalko I, Oboňa JV, Wehrs J, Morstein M, et al. A comparison of three different notching ions for small-scale fracture toughness measurement. Scripta Materialia 2016;112:71-4.

Jaya BN, Wheeler JM, Wehrs J, Best JP, Soler R, Michler J, et al. Microscale Fracture Behavior of Single Crystal Silicon Beams at Elevated Temperatures. Nano Letters 2016;16:7597-603.

Abad, O.T., et al., Temperature-dependent size effects on the strength of Ta and W micropillars. Acta Materialia, 2016. 103: p. 483-494.

Best, J.P., et al., Small-scale fracture toughness of ceramic thin films: the effects of specimen geometry, ion beam notching and high temperature on chromium nitride toughness evaluation. Philosophical Magazine, 2016. 96(32-34): p. 3552-3569.

Chen, M., et al., High-Temperature In situ Deformation of GaAs Micro-pillars: Lithography Versus FIB Machining. JOM, 2016. 68(11): p. 2761-2767.

Edwards, T.E.J., et al., Deformation of lamellar TiAl alloys by longitudinal twinning. Scripta Materialia, 2016. 118: p. 46-50.

Guo, Y., et al., On the nucleation and growth of {112¯ 2} twin in commercial purity titanium: In situ investigation of the local stress field and dislocation density distribution. Acta Materialia, 2016. 120: p. 292-301.

Jaya, B.N., et al., Microscale fracture behavior of single crystal silicon beams at elevated temperatures. Nano letters, 2016. 16(12): p. 7597-7603.

Jun, T.-S., et al., Local deformation mechanisms of two-phase Ti alloy. Materials Science and Engineering: A, 2016. 649: p. 39-47.

Jun, T.-S., et al., Local strain rate sensitivity of single α phase within a dual-phase Ti alloy. Acta Materialia, 2016. 107: p. 298-309.

Kermouche, G., et al., Perfectly plastic flow in silica glass. Acta Materialia, 2016. 114: p. 146-153.

Kolb, M., et al., Local mechanical properties of the (β0+ ω0) composite in multiphase titanium aluminides studied with nanoindentation at room and high temperatures. Materials Science and Engineering: A, 2016. 665: p. 135-140.

Mohanty, G., et al., Room temperature stress relaxation in nanocrystalline Ni measured by micropillar compression and miniature tension. Journal of Materials Research, 2016. 31(8): p. 1085-1095.

Tumbajoy-Spinel, D., et al., Assessment of mechanical property gradients after impact-based surface treatment: application to pure α-iron. Materials Science and Engineering: A, 2016. 667: p. 189-198.

Wheeler, J.M., et al., The effect of size on the strength of FCC metals at elevated temperatures: annealed copper. Philosophical Magazine, 2016. 96(32-34): p. 3379-3395.

Wheeler, J.M., et al., The plasticity of indium antimonide: Insights from variable temperature, strain rate jump micro-compression testing. Acta Materialia, 2016. 106: p. 283-289.

Zhang, Z., et al., Determination of Ti-6242 α and β slip properties using micro-pillar test and computational crystal plasticity. Journal of the Mechanics and Physics of Solids, 2016. 95: p. 393-410.

Zou, Y., et al., Bridging room-temperature and high-temperature plasticity in decagonal Al–Ni–Co quasicrystals by micro-thermomechanical testing. Philosophical Magazine, 2016. 96(32-34): p. 3356-3378.

2015

Mohanty G, Wheeler JM, Raghavan R, Wehrs J, Hasegawa M, Mischler S, et al. Elevated temperature, strain rate jump microcompression of nanocrystalline nickel. Philosophical Magazine 2015;95:1878-95.

Wehrs J, Mohanty G, Guillonneau G, Taylor AA, Maeder X, Frey D, et al. Comparison of In Situ Micromechanical Strain-Rate Sensitivity Measurement Techniques. JOM 2015; 67:1684-93.

Wheeler J, Armstrong D, Heinz W, Schwaiger R. High temperature nanoindentation: The state of the art and future challenges. Current Opinion in Solid State and Materials Science 2015;19:354-66.

Raghavan R, Wheeler J, Esqué-de los Ojos D, Thomas K, Almandoz E, Fuentes G, et al. Mechanical behavior of Cu/TiN multilayers at ambient and elevated temperatures: Stress-assisted diffusion of Cu. Materials Science and Engineering: A 2015;620:375-82.

2014

Soler R, Wheeler JM, Chang H-J, Segurado J, Michler J, Llorca J, et al. Understanding size effects on the strength of single crystals through high-temperature micropillar compression. Acta Materialia 2014;81:50-7.

Schwiedrzik J, Raghavan R, Bürki A, LeNader V, Wolfram U, Michler J, et al. In situ micropillar compression reveals superior strength and ductility but an absence of damage in lamellar bone. Nature materials 2014;13:740-7

2013

Wheeler J, Michler J. Elevated temperature, nano-mechanical testing in situ in the scanning electron microscope. Review of Scientific Instruments 2013;84:045103.

Rabier J, Montagne A, Wheeler J, Demenet J, Michler J, Ghisleni R. Silicon micropillars: high stress plasticity. Phys Status Solidi 2013;10:11-5

2012

Wheeler J, Brodard P, Michler J. Elevated temperature, in situ indentation with calibrated contact temperatures. Philosophical Magazine 2012;92:3128-41.

Wheeler J, Raghavan R, Michler J. Temperature invariant flow stress during microcompression of a Zr-based bulk metallic glass. Scripta Materialia 2012;67:125-8.

2011

Ghisleni R, Liu J, Raghavan R, Brodard P, Lugstein A, Wasmer K, et al. In situ micro-Raman compression: characterization of plasticity and fracture in GaAs. Philosophical Magazine 2011;91:1286-92.

Wheeler J, Raghavan R, Michler J. In situ SEM indentation of a Zr-based bulk metallic glass at elevated temperatures. Materials Science and Engineering: A 2011;528:8750-6.

2008

Wasmer K, Wermelinger T, Bidiville A, Spolenak R, Michler J. In situ compression tests on micron-sized silicon pillars by Raman microscopy—Stress measurements and deformation analysis. Journal of Materials Research 2008;23:3040-7.