How to couple electron backscatter diffraction with micromechanical testing?

For materials scientists and researchers, understanding the intricate relationship between a material’s microstructure and its mechanical properties is paramount. Electron backscatter diffraction (EBSD) offers a window into the crystallographic orientation of materials, while micromechanical testing provides insights into their mechanical behavior. Combined, these techniques can reveal a wealth of information about deformation mechanisms, damage initiation, and overall material performance.

Step-by-Step Process to Couple EBSD with Micromechanical Testing

1. Sample Preparation: The Foundation of Accurate Results

The first step in this methodical approach is preparing the sample for both EBSD and micromechanical testing. Achieving a mirror finish through polishing is essential for EBSD, as it ensures accurate data collection. Additionally, etching the sample will reveal its microstructure, allowing for clearer analysis. For micromechanical testing, the sample should be meticulously cut and shaped to the desired geometry, ensuring that it fits the testing apparatus and provides reliable results.

2. EBSD Analysis: Deciphering Crystallographic Orientation

Once the sample is prepared, it’s time to perform the EBSD analysis. This technique determines the crystallographic orientation of the material, a crucial piece of information for materials scientists. By understanding this orientation, professionals can predict and identify the deformation mechanisms that might occur during subsequent micromechanical tests.

3. Micromechanical Testing: Probing Mechanical Behavior

With the EBSD data in hand, researchers can proceed with micromechanical testing. Techniques such as nanoindentation, microcompression, or microtensile testing are employed to study the material’s deformation and fracture behavior. One of the significant advantages of coupling these techniques is the ability to observe material behavior in real-time using EBSD, providing a dynamic view of the deformation processes.

4. Data Analysis: Correlating Microstructure with Mechanical Properties

The final step involves a thorough analysis of the results. By correlating the EBSD data with observations from micromechanical testing, researchers can draw connections between the material’s crystallographic orientation and its mechanical behavior. This correlation offers invaluable insights into the microstructure and mechanical properties of materials at the microscale, enhancing the depth and breadth of understanding for materials scientists.

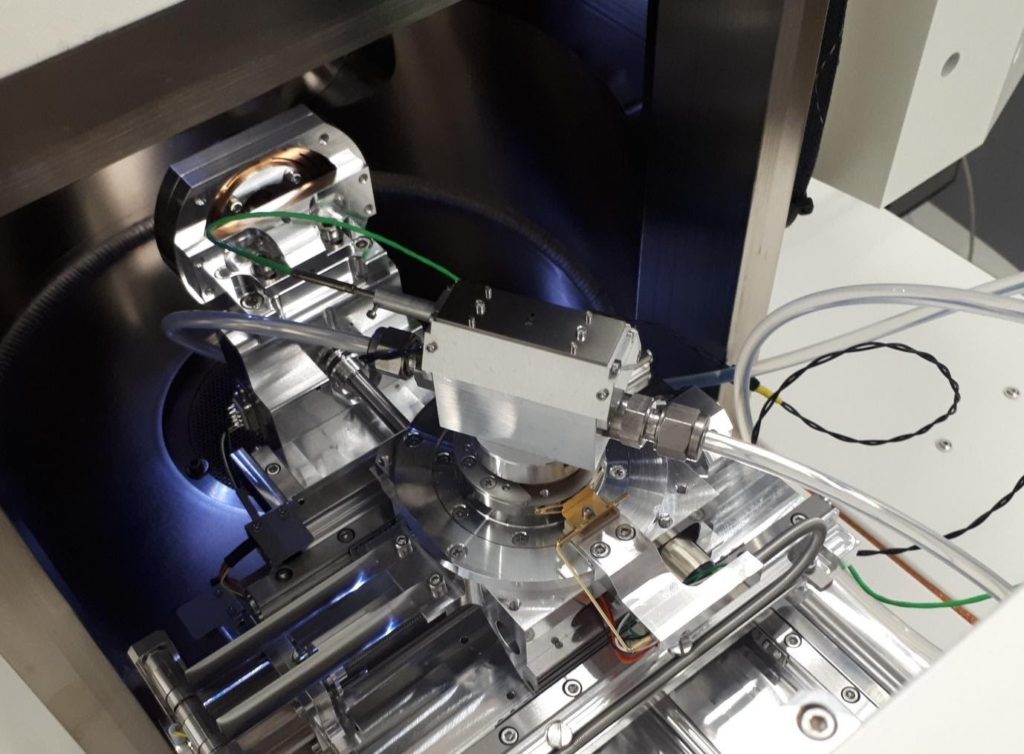

The Role of Alemnis in Advancing Micromechanical Testing

Alemnis AG stands at the forefront of micro- and nanomechanical property measurement. With a suite of instruments designed for in-situ material testing, we are committed to advancing the field and providing tools that enable researchers to delve deeper into the intricacies of material behavior. By offering solutions that facilitate the coupling of EBSD with micromechanical testing, we play a pivotal role in the ongoing exploration of materials at the micro and nano scales.

In the ever-evolving field of materials science, the coupling of electron backscatter diffraction with micromechanical testing represents a significant leap forward. By enabling more comprehensive characterization of materials, this combination paves the way for breakthroughs in understanding deformation processes and material performance.

At Alemnis, we recognize the potential of this synergy and invite researchers and professionals to explore our range of instruments.