Nanoindentation is a unique testing method used to assess various sample properties as a function of extremely small-scale surface deformation. Generally compact in design, nanoindentation systems can be utilized in a diverse set of applications for both organic and inorganic sample types. Biomaterials, ceramics, hard coatings, polymers, semiconductors, thin films, and more can routinely be analyzed using nanoindentation to determine numerous mechanical and dynamic characteristics.

In this blog post, Alemnis explores the properties that can be measured by nanoindentation.

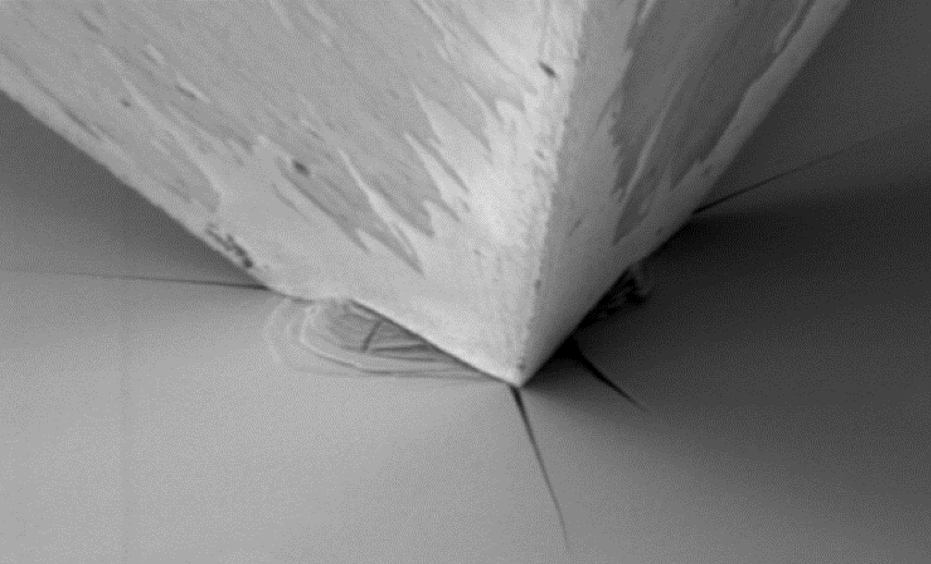

Cracking and Fracture Toughness

Nanoindentation of brittle solid materials like ceramics often causes lateral cracks to form around the impression. These may extend across the surface or nucleate beneath it, each of which can contribute towards important end-product phenomena. Cracking, particularly nucleation, is primarily indicative of a material’s fracture toughness.

Fracture toughness defines a material’s resistance to catastrophic failure when pre-existing flaws propagate through the product. Determining the fracture toughness of a given sample requires an understanding of its Young’s modulus and the dimensions of the defect. These are used to determine the stress intensity factor; a critical parameter for measuring the force per unit of surface area required for voids and cracks to propagate and cause materials to fail.

Nanoindentation measures Creep Deformation

Creep, or cold flow, is a measure of resistance to slow deformation in response to sustained mechanical stress. Nanoindentation can calculate the creep characteristics of a material by observing the increase in indenter tip depth as a function of time, as it is pressed into the sample surface at a constant force. This demands absolute precision and thermal stability of the nanoindentation system.

Nanoindentation detects Dislocation Nucleation

In materials science, dislocation nucleation occurs when the atomic bonds along a line in a lattice rupture due to shear forces. Homogenous dislocation nucleation requires many atomic bonds to break simultaneously which requires significant levels of shear stress. Nanoindentation is subsequently used to provide quantitative insights into material behavior at the onset of plasticity which is believed to contribute to dislocation, such as metal slipping or twinning.

Elastic Modulus and Hardness

Otherwise known as Young’s modulus, the elastic modulus of a material determines its resistance to deformation by compressive or bending forces. It is defined by the constant ratio of tensile stress to strain within the material’s elastic limits and can be used to calculate the applied tensile forces required for the material to plastically deform. The elastic modulus is intrinsically linked to both stiffness and hardness.

Nanoindentation was developed specifically for localized hardness testing of materials and has proven instrumental in testing their elastic moduli. As the elastic response of the surface sample is non-permanent, when the applied load of the nanoindenter tip is released, the sample surface will return to its original shape. Nanoindentation exceeds other hardness testing methodologies as it can also provide quantitative insight into elasticity.

Storage and Loss Moduli

Measuring the properties of viscoelastic samples with fixed geometries requires dynamic mechanical testing capable of acquiring storage and loss moduli. These refer to the measure of energy stored and lost in the elastic and viscous portions of the sample in response to linear stress. This is increasingly important for testing the properties of proprietary polymers and emerging biomaterials.

If you would like to learn more about the unique Almenis solution for nanoindentation testing, see our Product page

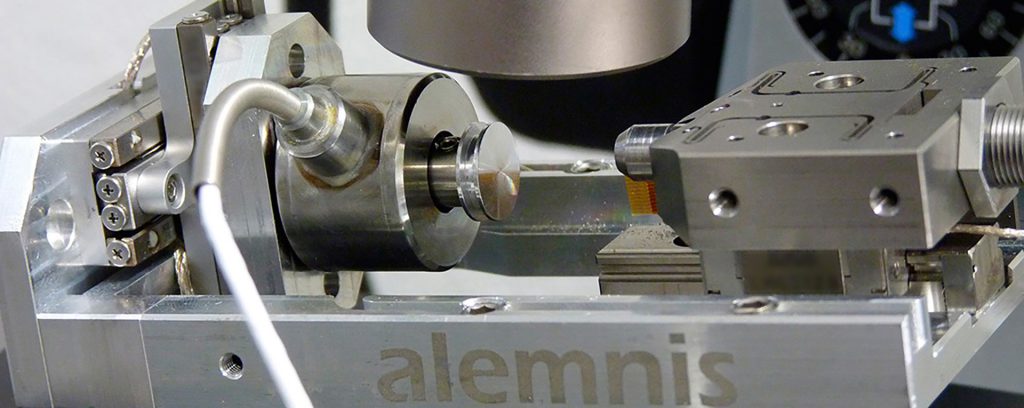

Nanoindentation with Alemnis

Alemnis specializes in small-scale mechanical testing for materials science research, offering a system equipped for both compression or tension modes. We can help you measure all the above properties and more.

Otherwise, contact us directly with any questions about our nanoindentation capabilities.

Selected references

- D. Tabor, Proc. R. Soc. A, 192 (1948) 247 (See article)

- M. F. Doerner, D. S. Gardner and W. D. Nix, J. Mater. Res., 1 (1986) 845-851 (See article)

- W. C. Oliver and G. M. Pharr, J. Mater. Res., 7 (1992) 1564-1583 (See article)

- N. X. Randall, R. Christoph, S. Droz, C. Julia-Schmutz, Thin Solid Films, 290-291 (1996) 348-354 (See article)