High Temperature Testing

Alemnis pioneered in situ high temperature micromechanical experiments, and has ever since continued the development to provide convenient and reliable experimenting. At a maximum temperature of 1000 °C, robustness is key to guarantee safe operation and minimal experimental time. This is where the Alemnis HTM series (High Temperature Module) excels with its unique design. The add-on modules for rated to different maximum temperatures (400 °C, 800 °C, and 1000 °C) are developed with a number of key concepts in mind:

- Highest temperature stability

- Most precise thermal match between Tip and Sample

- Minimal thermal drift

- Constant system compliance across all temperatures

- Minimal thermal radiation

Selected Application Examples

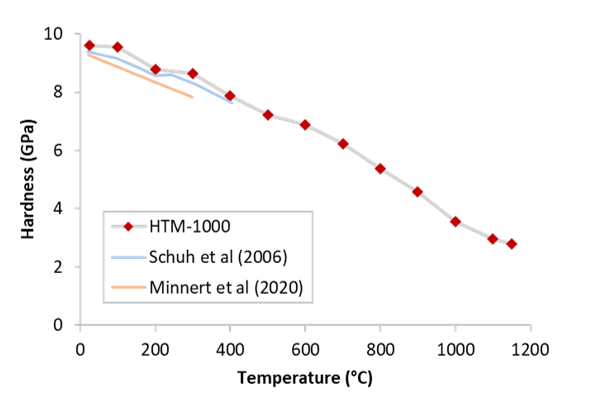

The hardness of fused silica as a function of temperature. Depending on the sample thickness, temperature even above 1000 °C can be reached.

ATSI: Automated Temperature Sweep Indentations

The Alemnis High Temperature Modules can now be utilised to perform automatic repeated indentation during a predefined heating ramp. This very recent development combines fast indentation mapping with our precise temperature control to automate the task of temperature-dependent nanoindention. By increasing the testing speed, we overcome thermal drift issue of transient states and enable thus an extremely efficient method for screening of high temperature properties.

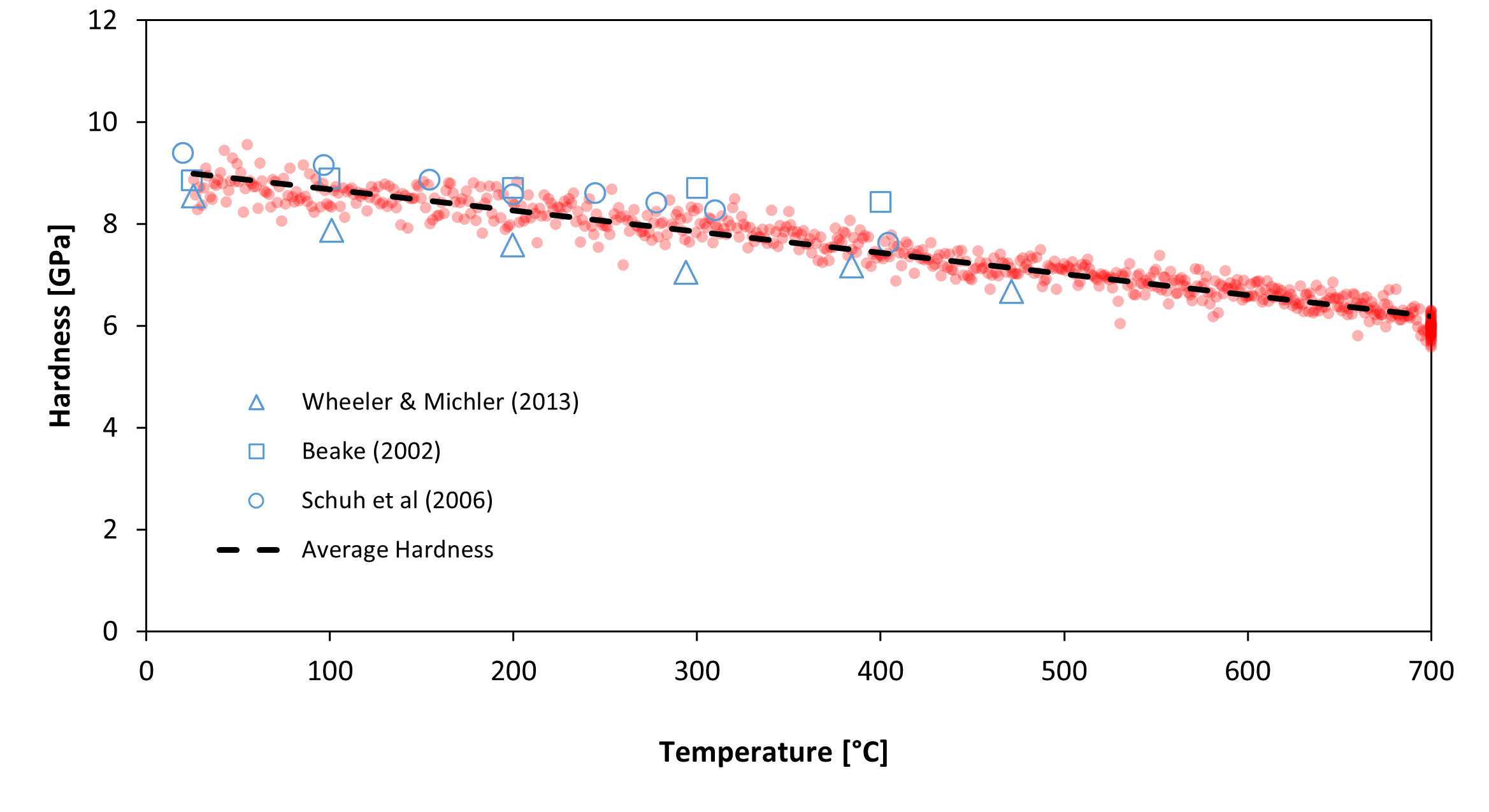

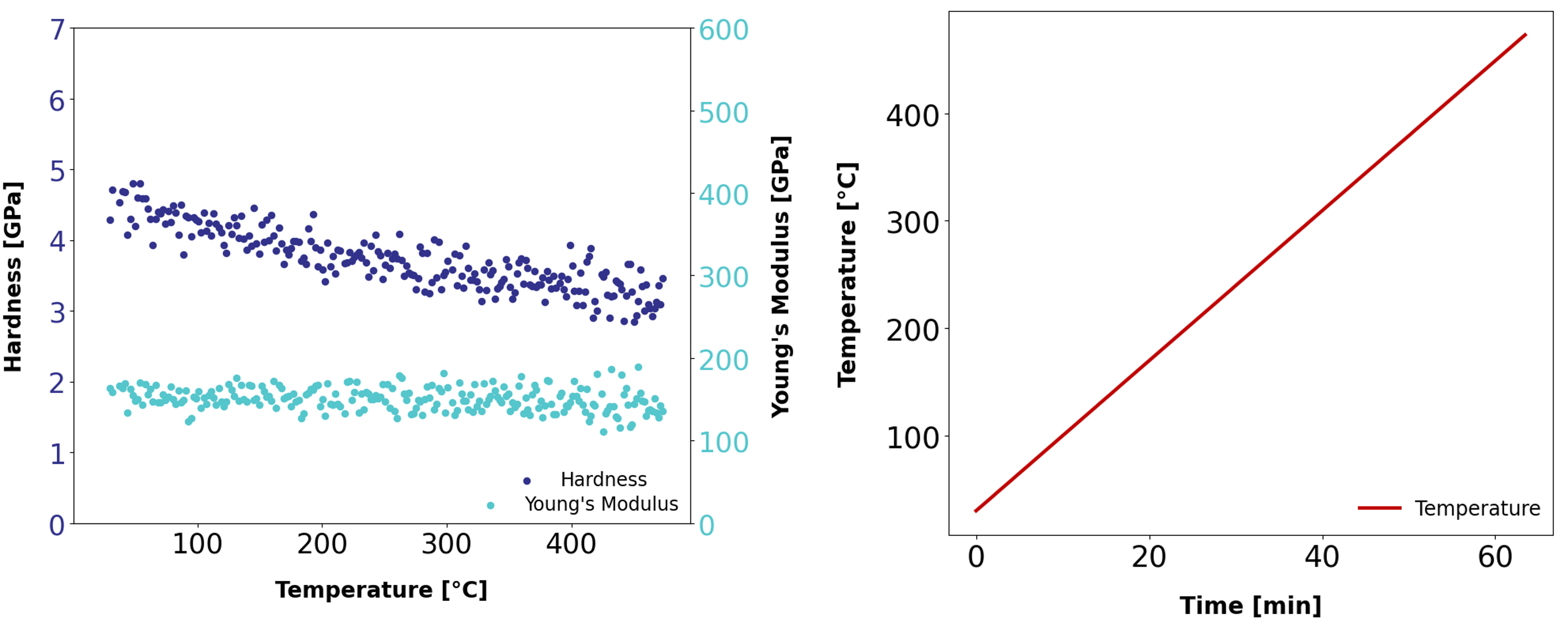

Determining high temperature mechanical properties becomes extremely efficient using Alemnis’ novel Automated Temperature Sweep Indentation method. Continuous (fast) indents were performed automatically during a temperature ramp of 7 °C/minute.

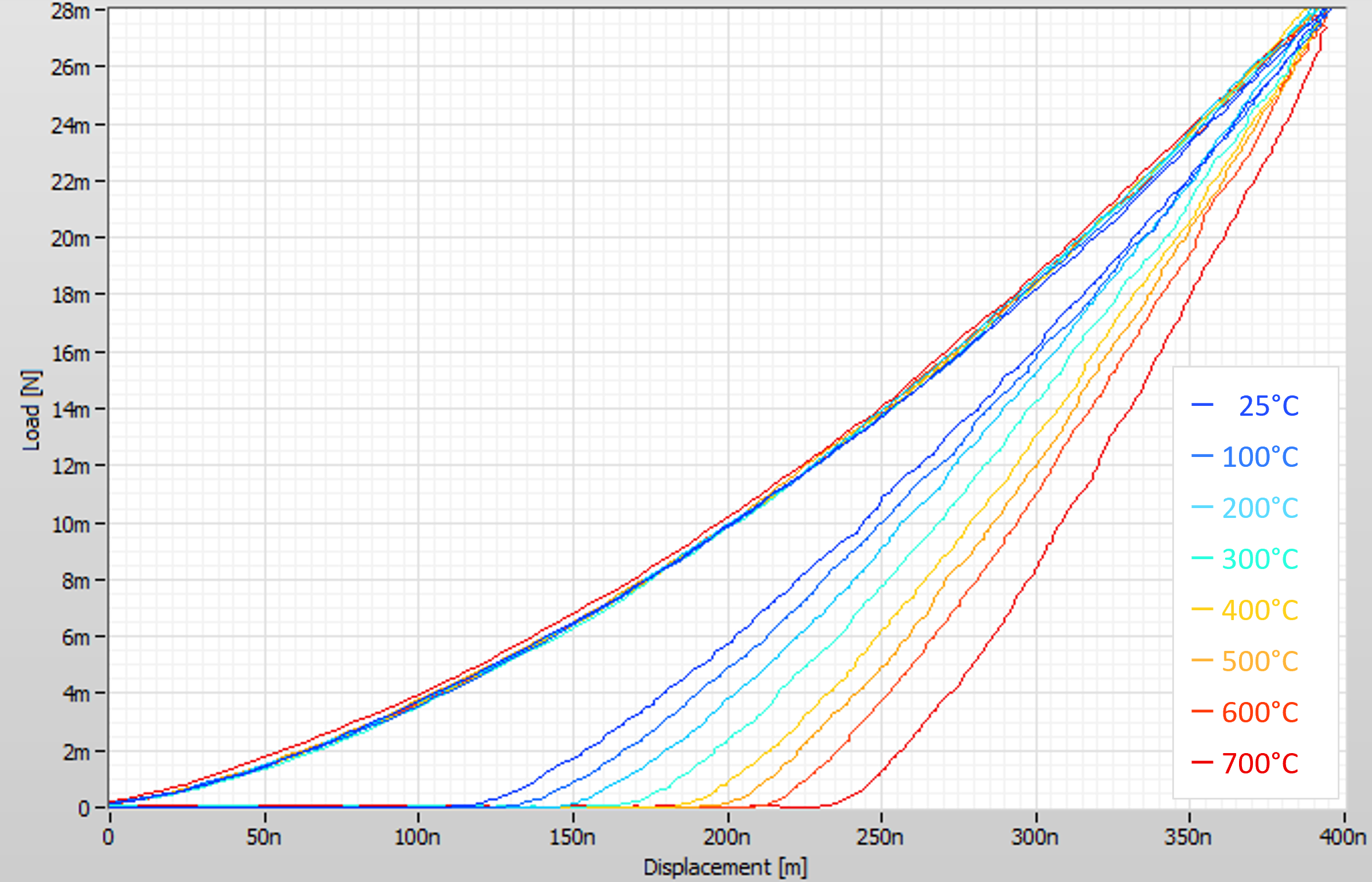

Representative load-displacement curves from Automated Temperature Sweep Indentation experiment on fused silica.

High temperature indentation hardness and elastic modulus of pure uranium obtained by Alemnis’ Automated Temperature Sweep Indentation method.

Micropillar compression

Micropillar compression remains one of the most popular techniques for high temperature studies thanks to the wealth of mechanical information that can be readily extracted from stress strain curves. The Alemnis High Temperature Modules combine several instrument characteristics that make it the number one choice for such experiments:

- True (intrinsic) displacement control

- Highest mechanical stiffness across the entire temperature range

- Strain rates up to 10/s at highest temperatures

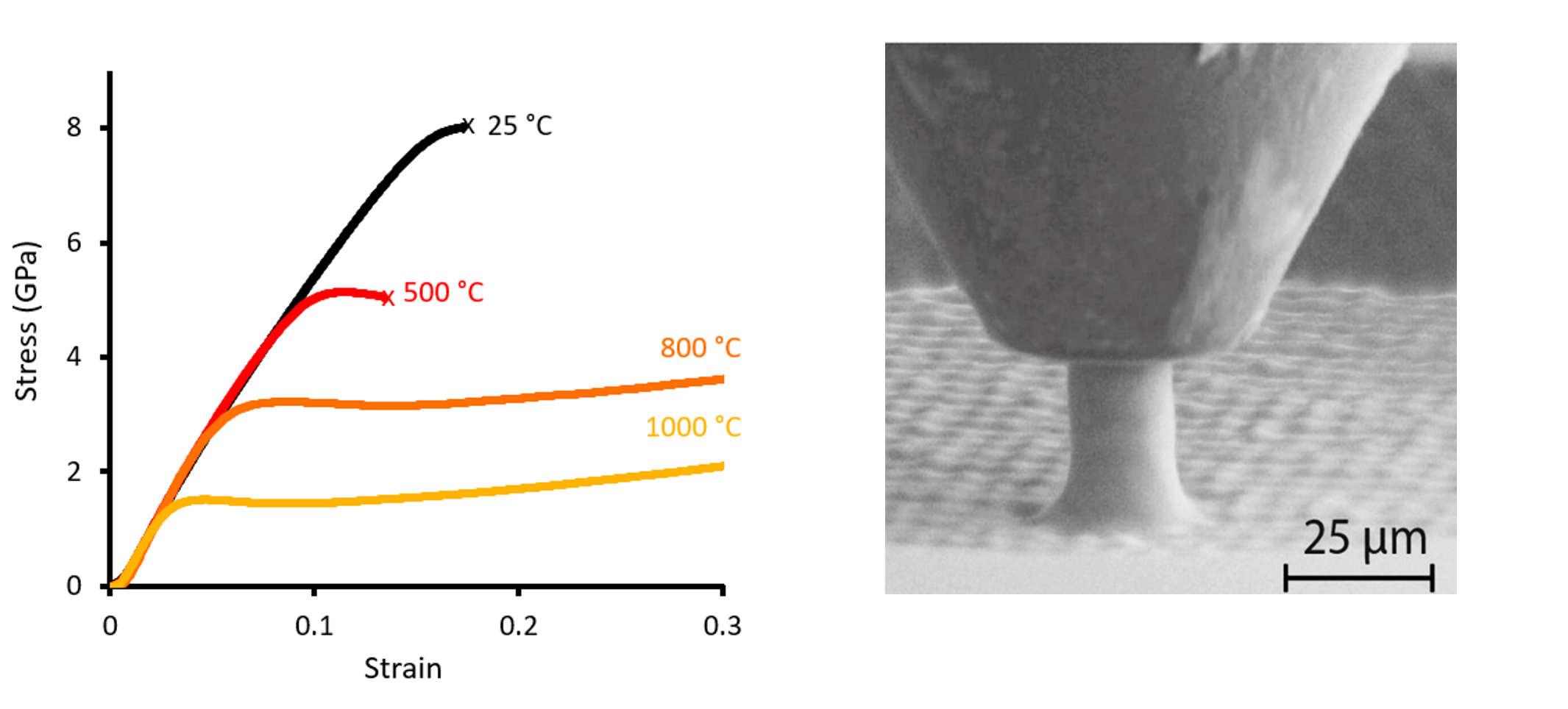

Micropillar compression of fused silica up to 1000 °C. A constant slope of the initial elastic loading across all temperatures indicates constant machine compliance, unaffected by temperature.

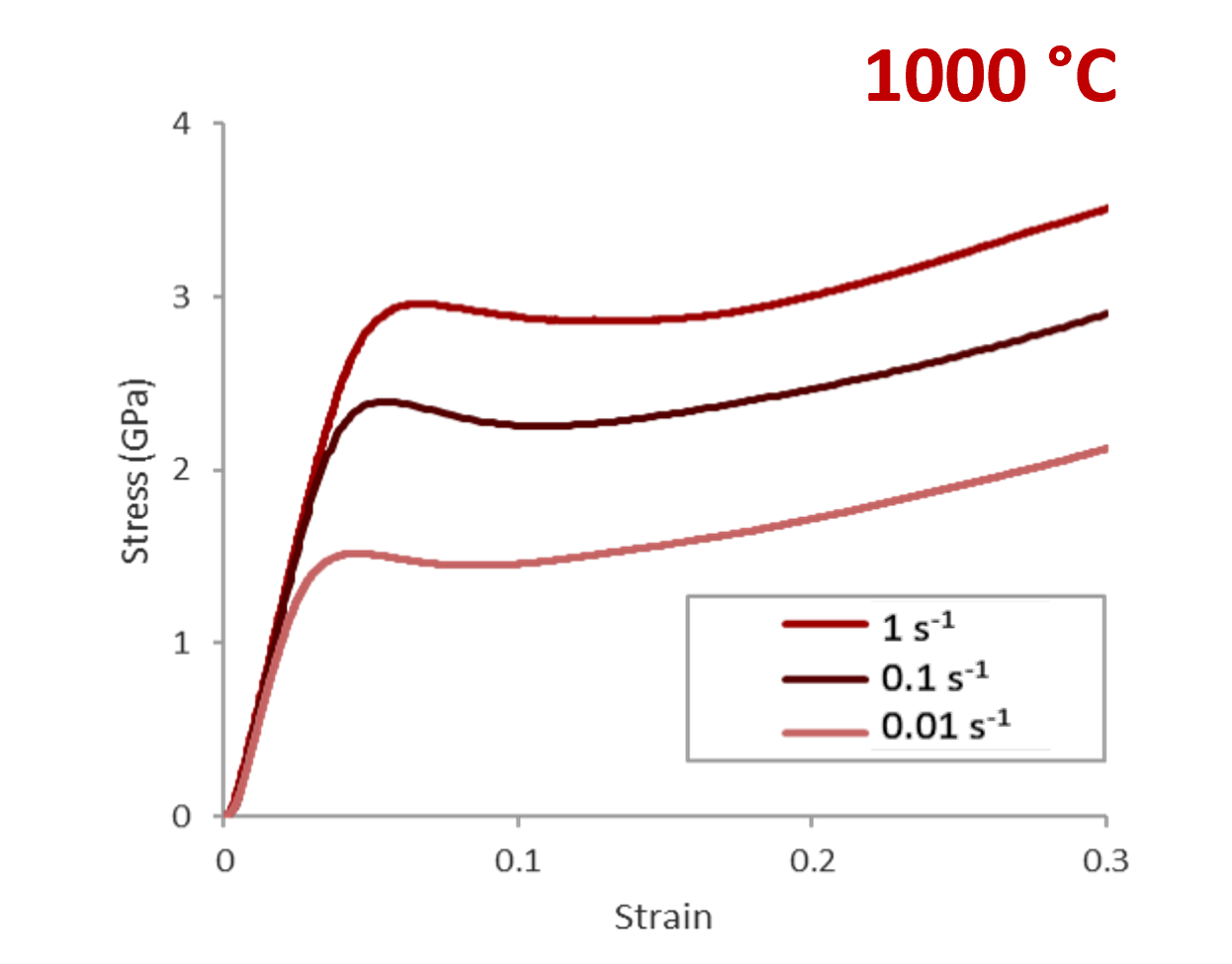

Strain rate dependent micropillar compression of fused silica at 1000 °C. Note: this pillar’s initial height is almost 40 µm. Using smaller pillars will enable even higher strain rates!

Selected References

- O. V. Pshyk, A. Vasylenko, P. Kuttel, B. Wicher, P. Schweizer, J. Michler, T. E. J. Edwards, Unlocking ultrastrong high-temperature ceramics: Beyond Equimolar Compositions in High Entropy Nitrides, arXiv preprint arXiv:2310.20441 (2023). https://doi.org/10.48550/arXiv.2310.20441.

- M. Jain, A. Sharma, K. Pajor, K. Wieczerzak, N. M. della Ventura, X. Maeder, J. J. Kruzic, B. Gludovatz, J. Michler, Mechanical properties and thermal stability of thin film metallic glass compared to bulk metallic glass from ambient to elevated temperatures, Journal of Alloys and Compounds 960 (2023) 170728. https://doi.org/10.1016/j.jallcom.2023.170728.

- R. N. Widmer, A. Groetsch, G. Kermouche, A. Diaz, G. Pillonel, M. Jain, R. Ramachandramoorthy, L. Pethö, J. Schwiedrzik, J. Michler, Temperature–dependent dynamic plasticity of micro-scale fused silica, Materials & Design 215 (2022) 110503. https://doi.org/10.1016/j.matdes.2022.110503.

- H. Jones, V. Tong, R. Ramachandramoorthy, K. Mingard, J. Michler, M. Gee, Micropillar compression of single crystal tungsten carbide, Part 1: Temperature and orientation dependence of deformation behaviour, International Journal of Refractory Metals and Hard Materials 102 (2022) 105729. https://doi.org/10.1016/j.ijrmhm.2021.105729.

- P. Jenczyk, D. M. Jarzabek, Z. Lu, E. Gadalińska, N. Levintant-Zayonts, Y. Zhang, Unexpected crystallographic structure, phase transformation, and hardening behavior in the AlCoCrFeNiTi0.2 high-entropy alloy after high-dose nitrogen ion implantation, Materials & Design 216 (2022) 110568. https://doi.org/10.1016/j.matdes.2022.110568.

- S. Wang, F. Giuliani, T. B. Britton, Variable temperature micropillar compression to reveal basal slip properties of Zircaloy-4, Scripta Materialia 162 (2019) 451–455. https://doi.org/10.1016/j.scriptamat.2018.12.014.

- T. E. J. Edwards, F. Di Gioacchino, A. J. Goodfellow, G. Mohanty, J. Wehrs, J. Michler, W. J. Clegg, Transverse deformation of a lamellar TiAl alloy at high temperature by in situ microcompression, Acta Materialia 166 (2019) 85–99. https://doi.org/10.1016/j.actamat.2018.11.050.

- J. P. Best, J. Wehrs, M. Polyakov, M. Morstein, J. Michler, High temperature fracture toughness of ceramic coatings evaluated using micro-pillar splitting, Scripta Materialia 162 (2019) 190–194. https://doi.org/10.1016/j.scriptamat.2018.11.013.