Cryogenic Testing

Alemnis pioneered in situ micromechanical experiments at low (cryogenic) temperatures, and has ever since continued the development to provide convenient and reliable experimenting. The Alemnis LTM-CRYO module utilizes liquid nitrogen to cool the sample and the tip down to temperatures as low as -150 °C while it can also be heated up to 200 °C. This add-on module was developed and optimised with the aim to provide a unique solution for cryo in situ micromechanical testing of all kinds of materials and features:

- Highest temperature stability

- Most precise thermal match between Tip and Sample

- Minimal thermal drift

- Constant system compliance across all temperatures

Selected Application Examples

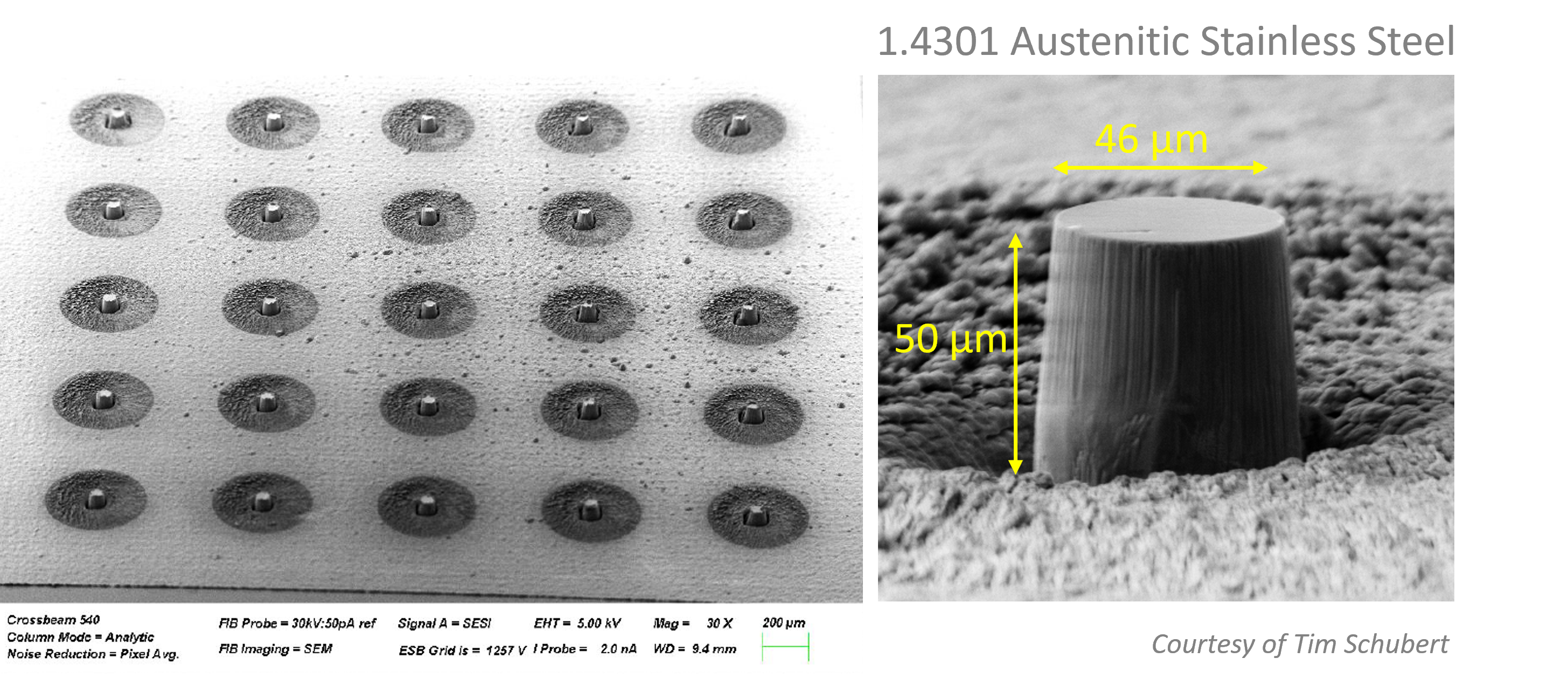

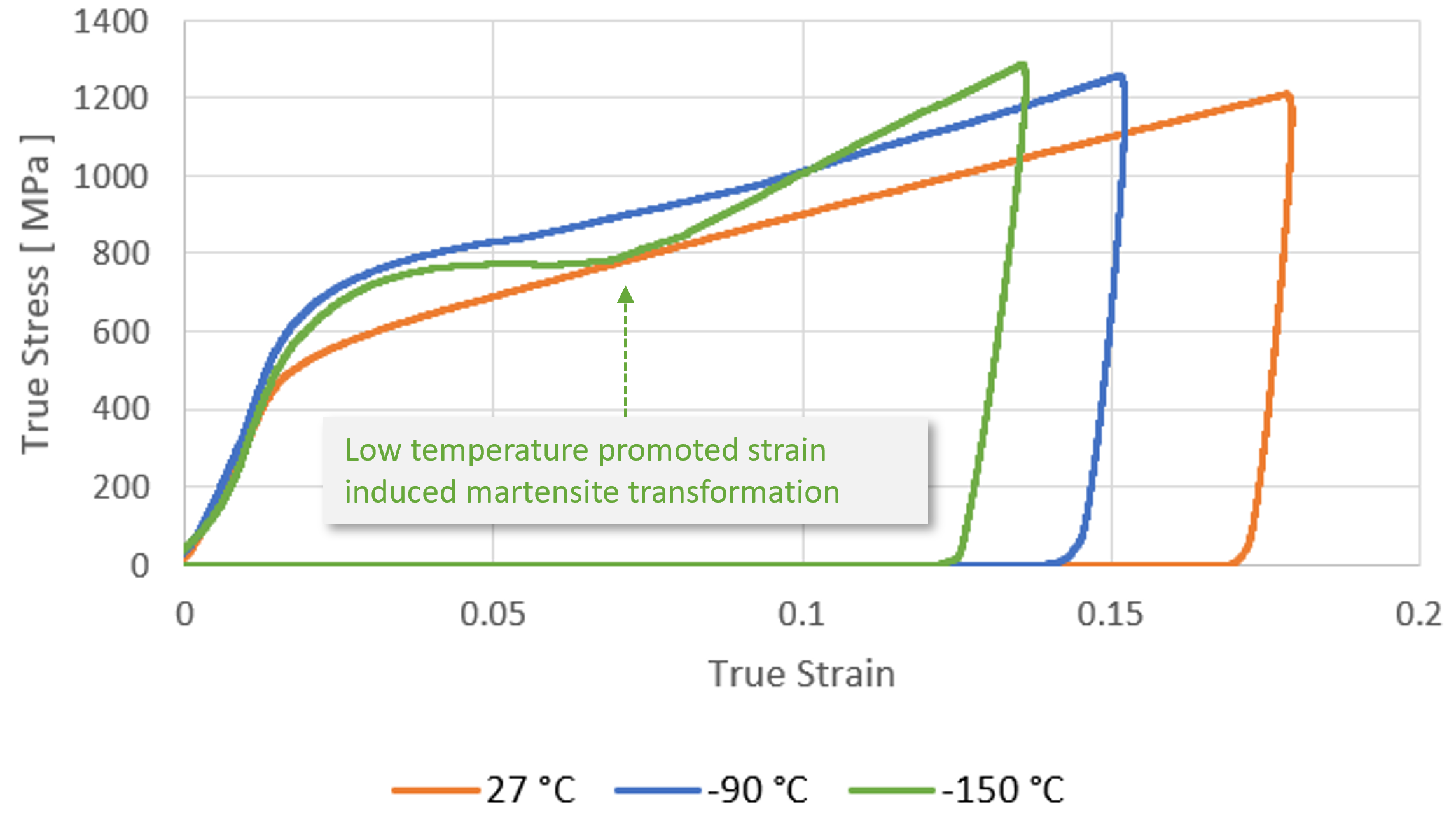

Micropillar compression

Micropillar compression of of 1.4305 stainless steel at low temperatures reveals strain-induced martensite transformation, as reported by Cios, G. et al. (Metall Mater Trans A 48, 4999–5008, 2017). Micropillars were fabricated by Fs-Laser with a final FIB polishing.

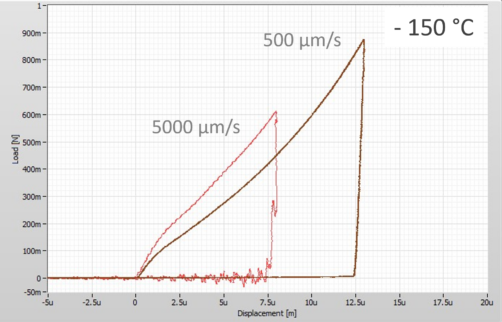

Particle compression at -150 °C from 500 µm/s up to 5’000 µm/s

Cryogenic testing combined with high strain rates: Stainless steel particle compression. (Courtesy of Politecnico di Milano)

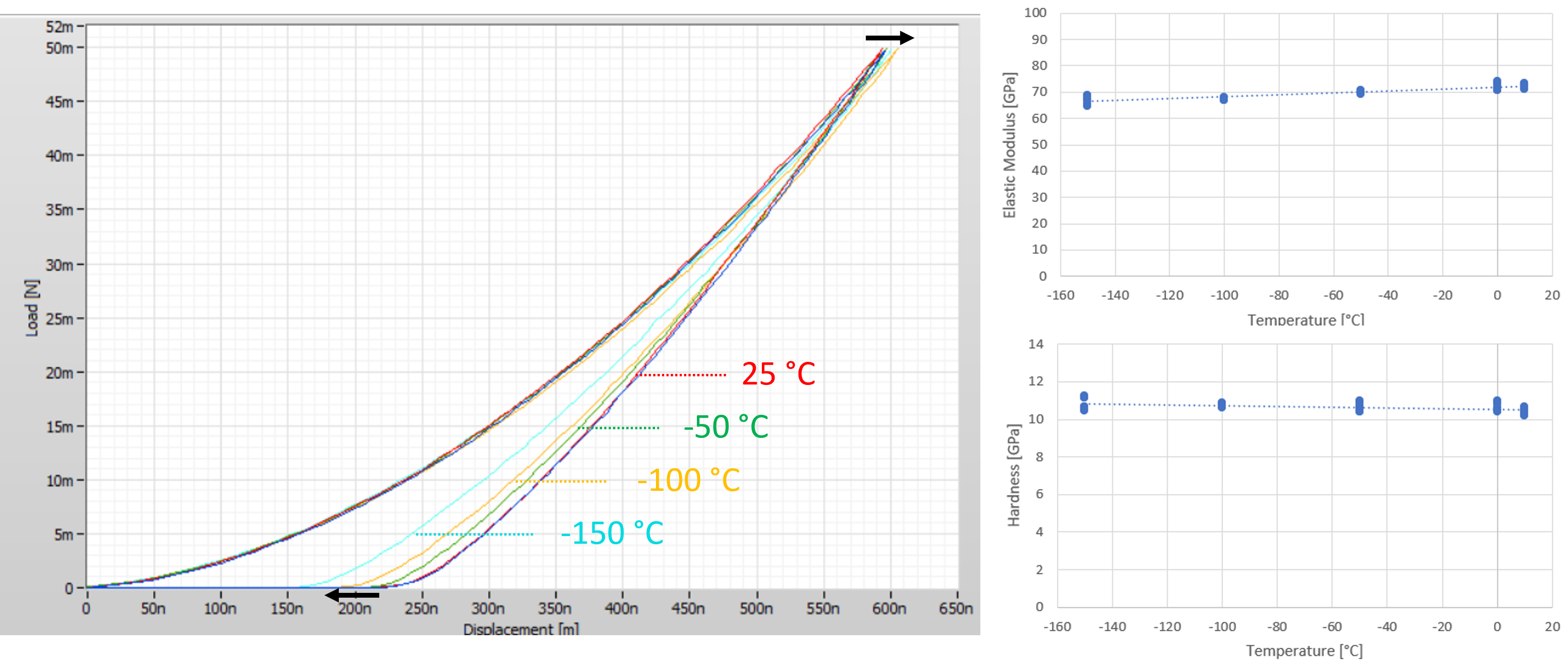

Nanoindentation

Nanoindentation of fused silica at low temperatures reveals the well-known trend of decreasing elastic modulus at increasing hardness.

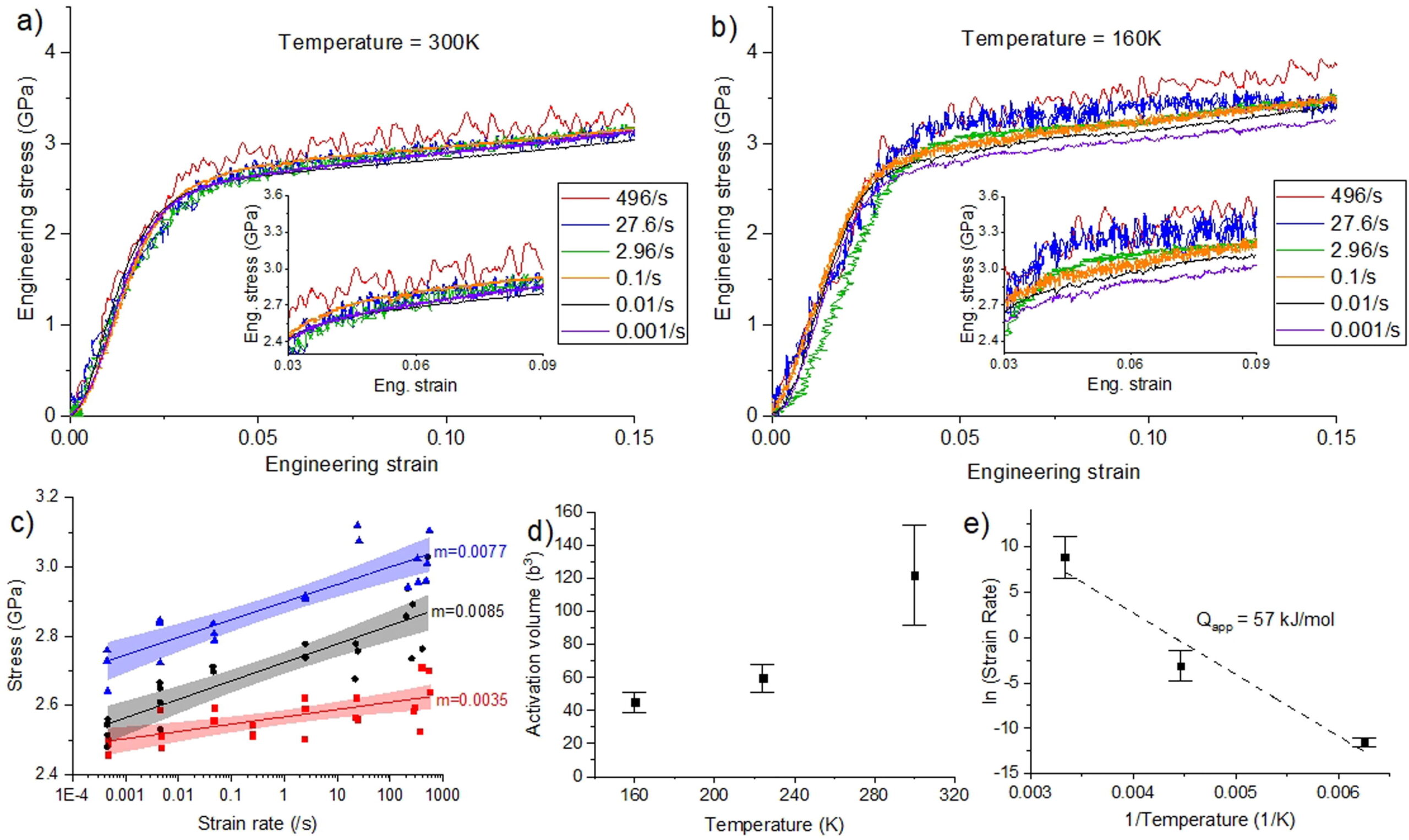

High Strain Rates at Low Temperatures

Nickle at Low Temperatures & High Strain Rates (Schwiedrzik, J. et al. Mater. Des. 2022, 220, 110836.)

Selected References

- M. Chen, A. S. Sologubenko, J. M. Wheeler, Exploring defect behavior and size effects in micron-scale germanium from cryogenic to elevated temperatures, Matter 6(6) (2023) 1903–1927. https://doi.org/10.1016/j.matt.2023.03.025.

- R. Dubosq, E. Woods, B. Gault, J. P. Best, Electron microscope loading and in situ nanoindentation of water ice at cryogenic temperatures, PLoS One 18 (2023) e0281703. https://doi.org/10.1371/journal.pone.0306374.

- N. M. della Ventura, C. Tian, A. Sharma, T. E. Edwards, J. J. Schwiedrzik, R. E. Loge, J. Michler, X. Maeder, Temperature dependent critical stress for {101¯ 2} twinning in magnesium micropillars at cryogenic temperatures, Scripta Materialia 226 (2023) 115195. https://doi.org/10.1016/j.scriptamat.2022.115195.

- J. Schwiedrzik, R. Ramachandramoorthy, T. E. Edwards, P. Schürch, D. Casari, M. J. Duarte, G. Mohanty, G. Dehm, X. Maeder, Laetitia Philippe, J.M. Breguet , J. Michler, Dynamic cryo-mechanical properties of additively manufactured nanocrystalline nickel 3D microarchitectures, Materials & Design 220 (2022) 110836. https://doi.org/10.1016/j.matdes.2022.110836.

- R. N. Widmer, A. Groetsch, G. Kermouche, A. Diaz, G. Pillonel, M. Jain, R. Ramachandramoorthy, L. Pethö, J. Schwiedrzik, J. Michler, Temperature–dependent dynamic plasticity of micro-scale fused silica, Materials & Design 215 (2022) 110503. https://doi.org/10.1016/j.matdes.2022.110503.

- K. Thomas, G. Mohanty, J. Wehrs, A. A. Taylor, S. Pathak, D. Casari, J. Schwiedrzik, N. Mara, R. Spolenak, J. Michler, Elevated and cryogenic temperature micropillar compression of magnesium–niobium multilayer films, Journal of Materials Science 54 (2019) 10884–10901. https://doi.org/10.1007/s10853-019-03422-x.

- J. Ast, J. J. Schwiedrzik, J. Wehrs, D. Frey, M. N. Polyakov, J. Michler, X. Maeder, The brittle-ductile transition of tungsten single crystals at the micro-scale, Materials & Design 152 (2018) 168–180. https://doi.org/10.1016/j.matdes.2018.04.009.