Nanoindentation and micro-compression tests are widely used to interrogate the mechanical properties of materials using either load or displacement control via an indenter tip of known geometry. This instrumented indentation principle has evolved from conventional methods of testing hardness, such as the Brinell or Vickers techniques and has emerged as the ideal candidate technology for evaluating a wide range of sample properties, such as hardness, elastic modulus, fracture toughness, creep, stress relaxation, strain rate sensitivity and slip deformation. However, material characteristics vary significantly with changes in temperature.

In some cases, the temperature dependence of material characteristics may have little-to-no implications for downstream applications. The same cannot be said of materials intended for use in thermal processing, refractory applications or as cutting tool coatings operating at high speeds and temperatures. Such materials must be characterized in simulated in-service temperatures, which can be challenging for conventional nanoindentation equipment.

In this blog post, Alemnis explores which nanoindenter materials are most suited for high-temperature testing.

Properties of High-Temperature Indenter Materials

Many of the challenges and quirks associated with assessing the mechanical properties of materials at elevated temperatures were first explored and overcome by hot hardness testing. This underlines many of the unique principles of high-temperature indentation. While indenter probes were initially chosen based on the highest possible hardness and stiffness, hot hardness tests demonstrated the importance of characterizing how these properties might change under test conditions.

Chosen indenter materials must retain their hardness at test temperatures, which often vary from room temperature up to 600°C (1112°F) in many industrial applications. Materials with poor coefficients of thermal expansion that exhibit exceptional hardness at room temperature may soften under test conditions. This can dramatically change the indenter area function, which in turn will cause an error in the subsequently calculated hardness or elastic modulus by a proportional amount. In addition, the indenter tip may become permanently damaged and lose its sharpness.

It is also important to assess mismatch in chemical reactivity between the indenter tip and the sample at high temperatures. Indenter materials that are inert at low temperatures may react with the sample material under test conditions, causing contamination of one or both materials in contact and, in extreme cases, dissolution of one material into the other.

Evaluating High-Temperature Indenter Materials

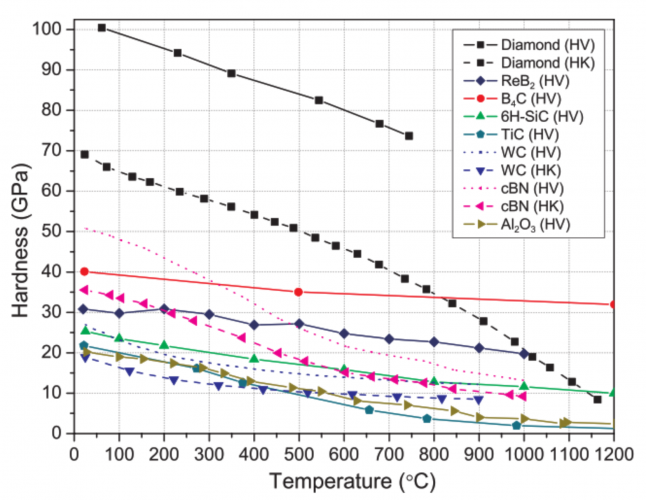

In order to perform a hardness test, the indenter material must be a minimum of 20% high hardness than the sample in order to generate plastic deformation. Ideally, the indenter should be > 100% harder in order to avoid rapid blunting or failure. A comprehensive analysis of high temperature indenter materials has been compiled by Wheeler and Michler (Ref. 1) and is shown in the hardness vs. temperature plot below. Although diamond is obviously one of the best indenter materials at ambient temperatures, its hardness decreases rapidly at elevated temperatures, although it still remains harder than all other candidates.

Diamond is the hardest engineering material available at all temperatures, from room temperature up to 1000°C (1832°F). It retains its exceptional intersection of mechanical properties throughout the most stringent high-temperature nanoindentation tests and remains the ideal solution for testing extremely hard materials like technical-grade ceramics and functional coatings. Cubic boron nitride (BN) is the next most noteworthy indenter material in terms of hardness at elevated temperatures, retaining its rigid structure up to operating temperatures of approximately 500°C (932°F) – after which it experiences an exponential drop in hardness.

Hot Vickers and Knoop hardness of indenter materials as a function of temperature with extrapolated Vickers hardness shown as dotted lines for materials where only Knoop hardness data were available (from Ref. 1)

While not as hard as cubic boron nitride, tungsten carbide (WC) is significantly better at retaining its hardness at high temperatures, with a maximum peak operating temperature of approximately 900°C (1652°F).

However, as mentioned, these material properties are merely one aspect of indenter performance. The risk of cross-contamination between the indenter tip, the sample, and oxygen molecules in the atmosphere is significantly increased at elevated temperatures. Oxide formation on indenter tips is practically unavoidable when heated to temperatures exceeding 400°C (752°F), for diamond, boron nitride, and sapphire (Al2O3). Tungsten carbide is one of the least reactive indenter materials at high temperatures, which enables its application for high-temperature nanoindentation testing of metal alloys.

In many ways, the material of the indenter tip must be diagnosed with some understanding of the material under test. While diamond and tungsten carbide represent the ideal frontrunners in terms of maintained mechanical properties and low reactivity, there are always exceptions that disprove the rule.

Reactivity poses an additional issue in that it may impose a temperature limitation on many nanoindentation apparatuses, with an average maximum operating temperature in air of 200°C (392°F). This may be sufficient for proprietary tests, but it will not provide accurate insights into the material hardness of refractories and high-performance alloys. A typical solution to this is to conduct heated indentation tests in vacuum conditions.

High-Temperature Nanoindentation Testing with Alemnis

Alemnis offers a range of High Temperature (HT) modules for precision testing of samples with a heated nanoindentation tip up to 1000°C (1832°F). These retrofittable modules are compatible with all standard indenter tip materials which can be simply and easily exchanged between experiments.

If you would like to learn more about our high temperature modules for nanoindentation testing, please do not hesitate to contact Alemnis.

- J. M. Wheeler and J. Michler, Indenter materials for high temperature nanoindentation, Review of Scientific Instruments 84 (2013) 101301