SYNCHROTRON/X-RAY

Several challenges exist when designing an in-situ mechanical testing assembly compatible with synchrotron beamlines. The assembly must be light weight as it must often be mounted on top of several motion stages. Also, the weight of the load frame must be distributed as symmetrically as possible about the rotational axis. In addition, the assembly must be sufficiently open to allow unrestricted passage of the X-ray beam.

The Alemnis Standard Assembly (ASA) fulfills all the aforementioned requirements for compatibility: it is lightweight yet rigid, axisymmetric about the rotational axis and has a very open architecture which is more than enough for experiments in static beamlines. For specific angles, or for full rotational tomography, the side-frame elements can be replaced with an X-ray transparent material (e.g., Polyether ether ketone, or PEEK).

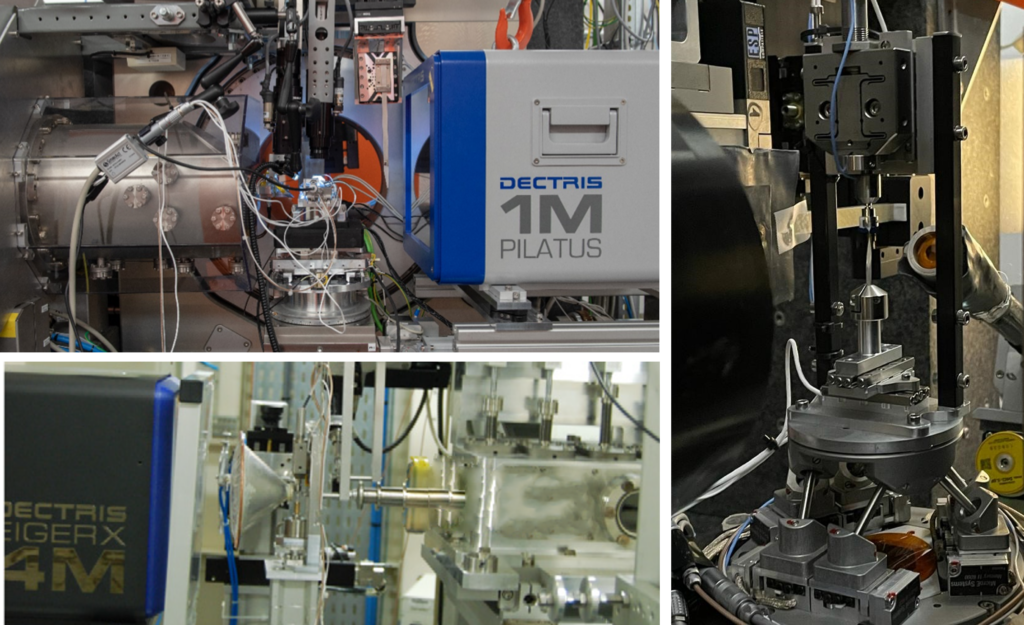

Alemnis Standard Assembly (ASA) mounted in various configurations on synchrotron X-ray beamlines. (Photos courtesy of S. Kalbfleisch, MAX IV Laboratory, Lund, Sweden, and X. Mäder and A. Groetsch, Empa, Thun, Switzerland)

The ASA can also be mounted together with an Integrated Microscope (IMI) which is an optical microscope with integrated illumination and allows a repositioning accuracy between the indenter and the focus point of 10 µm. Combining nanoindentation with X-ray diffraction (XRD) in a synchrotron beamline allows the study of many material properties. For example, a common experiment is to place the sample under a certain constant stress (usually achieved by holding the applied load over several hours) and map the induced elastic strain field in the deformation zone. Such studies can pave the way for studying strain profiles using synchrotron radiation during micromechanical testing of small volumes. In this way, the nanostructural origin of the observed strain evolution can be understood and correlated with the conditions of deformation.

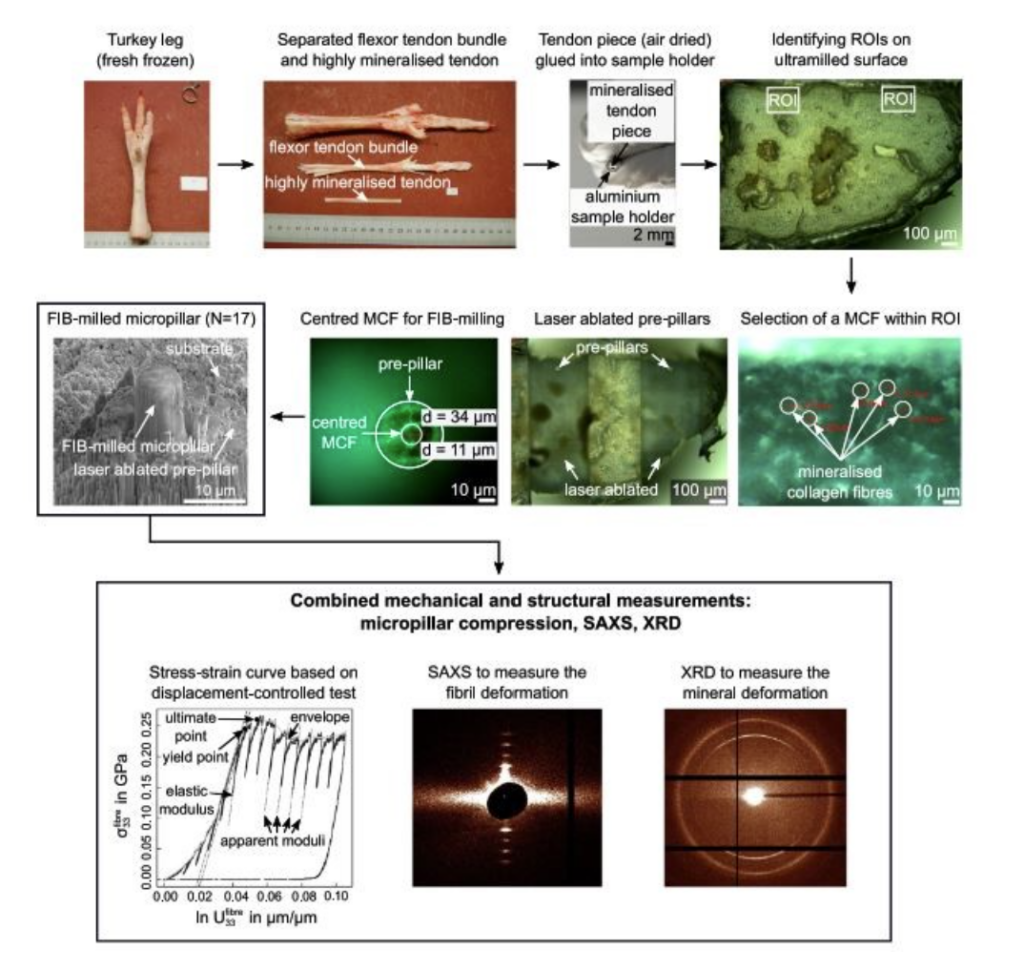

Explore our application on Micropillar compression of collagen fibers combined with X-ray scattering (SAXS) and X-ray diffraction (XRD) for more details.

Summary of preparation steps required to extract individual mineralized collagen fibres by means of dissection, ultra-milling, ultra-short pulsed laser ablation and focused ion beam milling. The SEM image shows the final micropillar which was compression tested whilst acquiring small angle X-ray scattering (SAXS) and X-ray diffraction (XRD) data.

Selected References

- J. Gamcová, G. Mohanty, Š. Michalik, J. Wehrs, J. Bednarčík, C. Krywka, J-M. Breguet, J. Michler, H. Franz, Mapping strain fields induced in Zr-based bulk metallic glasses during in-situ nanoindentation by X-ray nanodiffraction, Applied Physics Letters 108 (2016) 031907. https://doi.org/10.1063/1.4939981

- A. Bhowmik, G Sernicola, J Lee, T. B. Britton, W. Liu, T-S Jun, M. Karimpour, D. S. Balint, F. Giuliani, Deformation behaviour of [001] oriented MgO using combined in-situ nano-indentation and micro-Laue diffraction, Acta Materialia 145 (2018) 516-531. https://doi.org/10.1016/j.actamat.2017.12.002

- X. Tong, G. Wang, J. Bednarčík, Y. D. Jia, I. Hussain, J. Yi, Z. H. Stachurski, Q. J. Zhai, Structural evolution in a metallic glass pillar upon compression, Materials Science and Engineering A 721 (2018) 8–13. https://doi.org/10.1016/j.msea.2018.02.050.

- H. E. Weekes, V. A. Vorontsov, I. P. Dolbnya, J. D. Plummer, F. Giuliani, T. B. Britton, D. Dye, In situ micropillar deformation of hydrides in Zircaloy-4, Acta Materialia 92 (2015) 81–96. https://doi.org/10.1016/j.actamat.2015.03.037.

- A. Groetsch, A. Gourrier, J. Schwiedrzik, M. Sztucki, R. J. Beck, J. D. Shephard, J. Michler, P. K. Zysset, U. Wolfram, Compressive behaviour of uniaxially aligned individual mineralised collagen fibres at the micro- and nanoscale, Acta Biomaterialia 89 (2019) 313–329. https://doi.org/10.1016/j.actbio.2019.02.053.