STRESS RELAXATION

Stress relaxation is defined as the gradual reduction in stress with time at a constant strain. In practice, the strain is increased up to a preset value and held, after which the stress reduction can be monitored. The plastic deformation of many materials, especially metals and polymers, is known to be strongly time-dependent. Such viscoplasticity equates to a high degree of strain rate sensitivity (SRS) and susceptibility to creep and stress relaxation. Although the study of SRS and creep by nanoindentation and micropillar compression is fairly popular, the stress relaxation properties may actually be more important in certain applications, such as failure of MEMS devices when subjected to contact stresses in service. There is currently very little nanoindentation stress relaxation data available, probably because many conventional nanoindenters are unable to accurately measure stress relaxation because they are inherently load-controlled instruments and so have difficulties with maintaining constant strain.

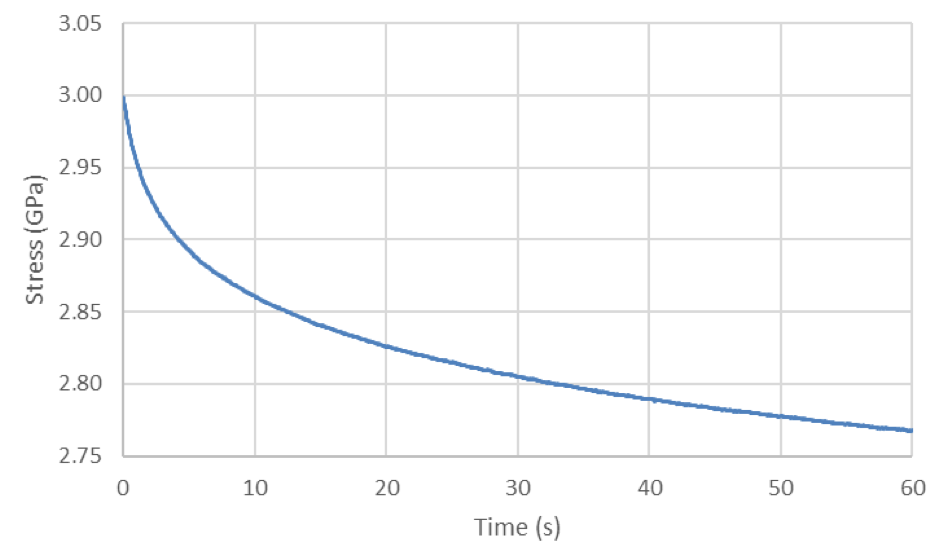

Example of a typical stress relaxation curve in the fully plastic flow regime for a micropillar compression test on nanocrystalline Ni (from Ref. 1)

Selected References

- G. Mohanty, J. Wehrs, B. L. Boyce, A. Taylor, M. Hasegawa, L. Philippe, J. Michler, Room temperature stress relaxation in nanocrystalline Ni measured by micropillar compression and miniature tension, Journal of Materials Research 31 (2016) 1085–1095. https://doi.org/10.1557/jmr.2016.101.

- T-S. Jun, Z. Zhang, G. Sernicola, F. P. E. Dunne, T. B. Britton, Local strain rate sensitivity of single α phase within a dual-phase Ti alloy, Acta Materialia 107 (2016) 298–309. https://doi.org/10.1016/j.actamat.2016.01.057.

- J. Wehrs, M. J. Deckarm, J. M. Wheeler, X. Maeder, R. Birringer, S. Mischler, J. Michler, Elevated temperature, micro-compression transient plasticity tests on nanocrystalline Palladium-Gold: Probing activation parameters at the lower limit of crystallinity, Acta Materialia 129 (2017) 124–137. https://doi.org/10.1016/j.actamat.2017.02.045.