CREEP

Indentation creep is defined as the relative change in the indentation depth whilst the applied load is kept constant. It is defined in the ISO 14577 instrumented indentation standard as CIT, as follows:

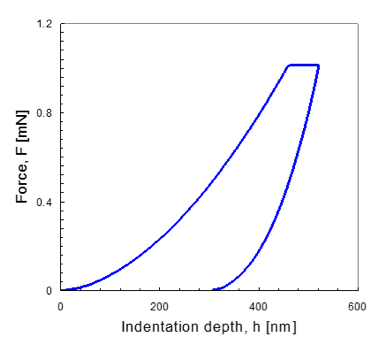

Where h1 is the depth at the beginning of the creep test and h2 the depth at the end of the creep test. In most quasi-static indentation or micropillar creep tests, the instrument is programmed to increase the load up to a fixed value, after which the load is paused and the displacement monitored over a defined time period before unloading.

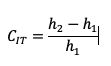

Example of a load depth curve (left) with a hold at maximum load for creep evaluation. The corresponding load (blue) and depth (red) profiles plotted as a function of time (right) show the increase in displacement whilst the load remains constant.

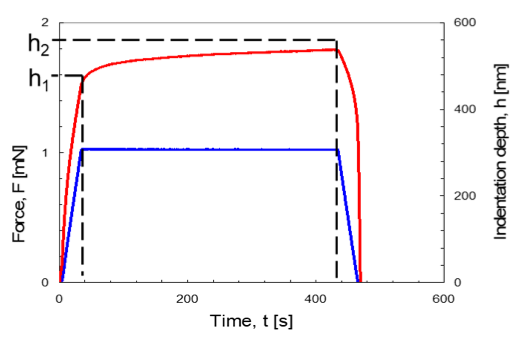

The displacement creep portion of the curve is commonly extracted and plotted as a function of time to give a “creep curve” which is usually of an exponential form. The creep rates of different materials can be compared by performing the same test and overlaying the creep curves as shown here for three different polymers.

Creep curves for 3 polymers by quasi-static nanoindentation with maximum load 1 mN and loading rate 2 mN/min.

The Alemnis Standard Assembly (ASA) is especially suited to long term creep experiments owing to its unparalleled stability. This has proved particularly useful for performing micromechanical experiments over very long time periods (hours), such as holding at a constant load for 8 hours whilst making X-ray diffraction (XRD) studies in synchrotron beamlines, or analyzing structural changes induced by nanoindentation.

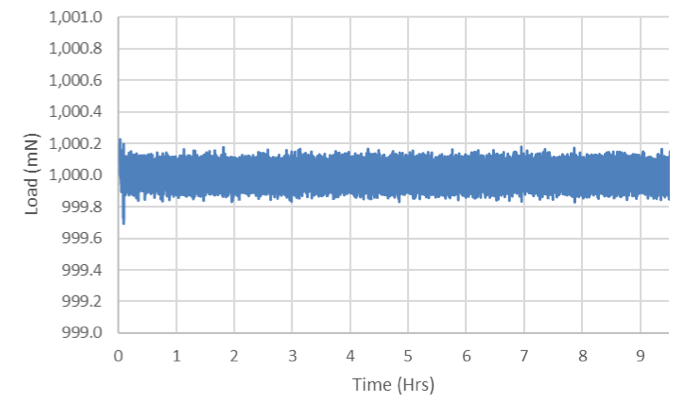

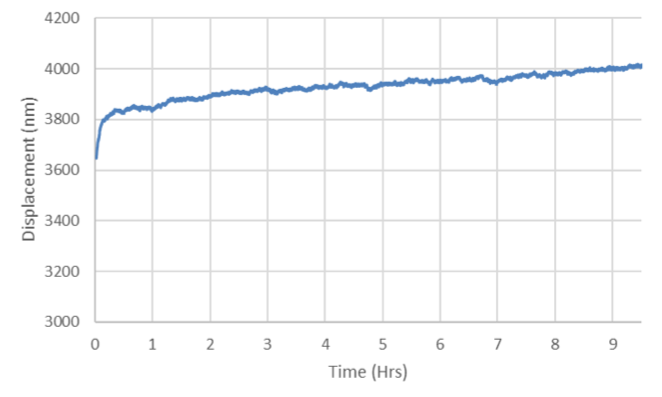

Long term creep test with 1 N applied load, Berkovich indenter, performed on a bulk metallic glass (BMG) ex-situ in the PETRA III synchrotron beamline at DESY, Germany. The load stability was 60 µN over 9.4 hours with a drift rate of < 30 nm (0.6 nm/min.) (From Ref. 1)

Selected References

- J. Gamcová, G. Mohanty, Š. Michalik, J. Wehrs, J. Bednarčík, C. Krywka, J. M. Breguet, J. Michler, and H. Franz, Mapping strain fields induced in Zr-based bulk metallic glasses during in-situ nanoindentation by X-ray nanodiffraction, Applied Physics Letters 108 (2016) 031907. https://doi.org/10.1063/1.4939981.