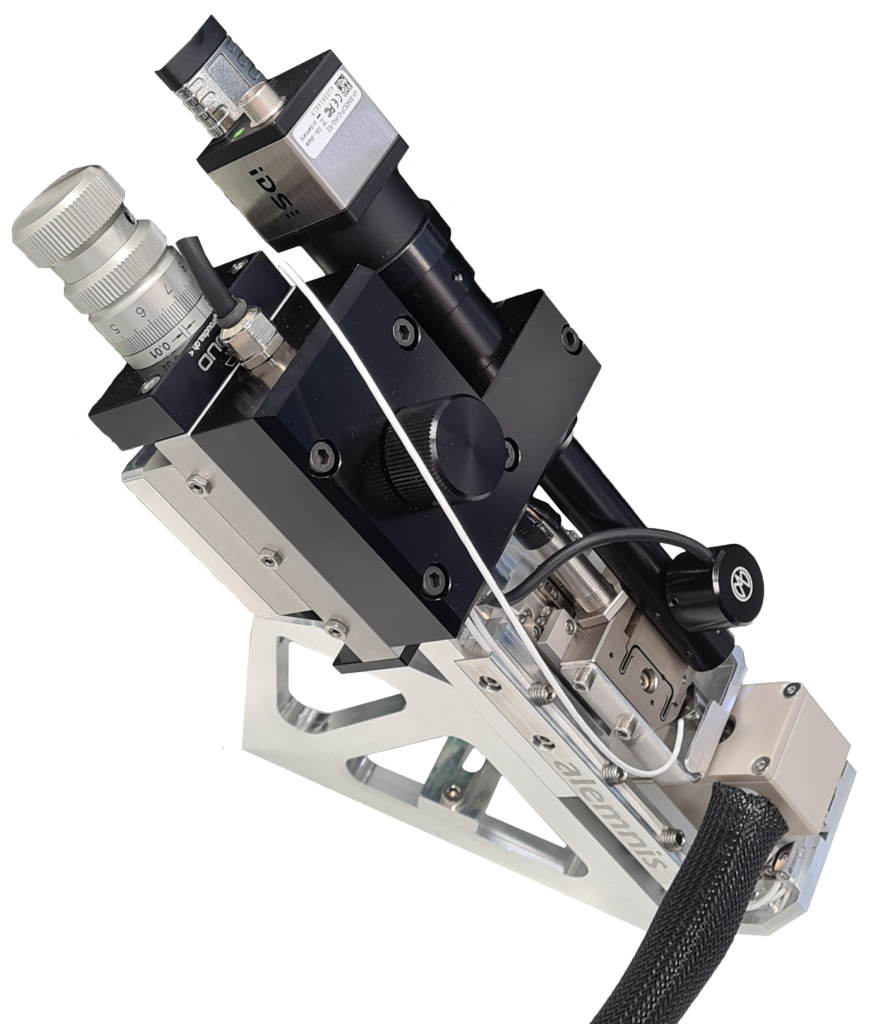

The Bio-indenter is an ex-situ variant of the Alemnis Standard Assembly (ASA) which is specifically designed for characterizing the mechanical properties of tissues and soft materials. It can be configured with the Relative Humidity Module (RHM) and the Miniaturized Load Cell (MLC) to provide a complete testing platform for a wide variety of sample configurations (micropillars, particles, gels, tensile testing, etc..) in a range of environments (controlled relative humidity and temperature, submerged in liquid, etc..). The basic specifications are as follows:

Applied load range: 10 µN – 500 mN (by choosing a different load sensor, the maximum range can be extended up to 4 N)

Load noise floor: 4 µN

Displacement range: up to 100 µm (using DHP-100)

Displacement noise floor: 1 nm

The Bio-indenter configuration can also be coupled with an optical microscope via a piezo-actuated XY displacement stage. The optical microscope has the following specifications:

- Objective with zoom (0.77 – 9.31x)

- Working distance 86mm

- Color camera 1280 x 1024 pixel

- Coaxial and annular illumination

The Bio-indenter has proved itself for many ground-breaking scientific studies:

Tensile Testing at the Microscale

Focused ion beam (FIB) was used to produce microtensile specimens to mimic ASTM 638 tensile specimen stress conditions. Single crystal Si and GaAs specimens were tested to validate the tensile setup.

Casari et al., European FIB Network, Grenoble, 2018

Tensile properties of bone extracellular matrix were evaluated in both axial and transverse orientations on the length scale of a single lamellae. Tensile test specimens were fabricated by focused ion beam (FIB) milling of ovine osteonal bone and two distinct failure modes were identified from in-situ observation and post-failure high resolution scanning electron micrographs.

Casari et al, World Congress of Biomechanics, Dublin, 2018

Low temperature (cryo) testing of nanocrystalline PdAu:

Development of the Low Temperature Module (LTM-CRYO) to investigate deformation mechanisms by strain rate jump micropillar compression experiments at temperatures down to 125 K with hardness mapped as a function of temperature.

Schwiedrzik et al., ECI Nanomechanical Testing, Dubrovnik, 2017